Refined tall oil price April 2024 and outlook (see chart below)

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Refined tall oil price chart

This post is a summary of the global refined tall oil price developments. The price developments of global refined tall oil are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Refined tall oil price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for global refined tall oil prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of global refined of refined tall oil

- Market futures for both cost drives and feedstocks of global refined tall oil

- Adjustment of current supply/demand imbalances in the refined tall oil

- Longer term trends in likely demand conditions

Further information on the refined tall oil price chart

What is Tall Oil

Tall oil is a natural co-product of the kraft pulping process used in the production of paper and pulp from wood, primarily from coniferous trees like pine. It is a dark, viscous liquid that contains a mixture of components, including:

Fatty Acids

Tall oil contains a significant amount of fatty acids, such as oleic acid and linoleic acid, which have various industrial applications.

Rosin

Rosin is a solid resin obtained from pine trees and is commonly used in products like adhesives, inks, and coatings.

Sterols

Sterols are naturally occurring compounds with various uses in the chemical and pharmaceutical industries.

Pitch

Pitch is a sticky substance that can be separated from tall oil and has applications in the manufacturing of adhesives and road construction.

Unsaponifiables

These are components that do not react with alkalis to form soap and can have applications in cosmetics and pharmaceuticals.

Tall oil is considered a valuable resource because it can be further processed to extract specific components like tall oil fatty acids (TOFA) and tall oil rosin (TOR). These extracted components have a wide range of industrial applications, including the production of soaps, detergents, adhesives, lubricants, and more. Additionally, tall oil and its derivatives are used in the manufacture of biofuels and as raw materials in various chemical processes

What is Tall Oil used for

Tall oil and its derivatives have a wide range of industrial applications due to their unique chemical composition. Here are some common uses for tall oil:

Soap and Detergent Production

Tall oil fatty acids (TOFA), which are derived from tall oil, are used as raw materials in the production of soaps and detergents. They provide lathering and cleaning properties to these products.

Adhesives and Sealants

Tall oil rosin (TOR), another derivative of tall oil, is used in the formulation of adhesives, sealants, and coatings. It enhances the tackiness and adhesive properties of these products.

Ink Manufacturing

Tall oil rosin is a key ingredient in the production of printing inks, including both lithographic and letterpress inks.

Paper Sizing

Tall oil fatty acids are used in the paper industry as sizing agents to improve the water resistance and printability of paper products.

Lubricants

Tall oil derivatives can be used as additives in lubricants to enhance their performance, particularly in the metalworking industry.

Mining Industry

Tall oil-based flotation agents are used in the mining industry to separate valuable minerals from ore by froth flotation processes.

Biofuels

Tall oil can be used as a feedstock in the production of biofuels, such as biodiesel and renewable diesel.

Emulsifiers

Tall oil fatty acids and their derivatives are used as emulsifiers in various applications, including in the production of emulsion paints.

Rubber Manufacturing

Tall oil derivatives are used as processing aids and tackifiers in the rubber industry.

Cosmetics and Personal Care

Some tall oil derivatives may be found in cosmetics and personal care products due to their emollient and moisturizing properties.

Pharmaceuticals

Certain tall oil components, such as sterols, have applications in the pharmaceutical industry.

Specialty Chemicals

Tall oil and its derivatives can be used in the formulation of specialty chemicals for a variety of industrial processes.

It’s important to note that the specific application of tall oil and its derivatives can vary depending on their grade, purity, and intended use. The versatility of tall oil makes it a valuable resource in various industries, contributing to the production of a wide range of products.

What types of Tall Oil are there

Tall oil is a complex mixture of components, and it can be further processed and separated into various types and derivatives depending on the specific applications and desired properties. Some of the primary types and derivatives of tall oil include:

Tall Oil Fatty Acids (TOFA)

Tall oil fatty acids are one of the most common and valuable derivatives of tall oil. They are obtained by distilling and refining tall oil. TOFA is used in the production of soaps, detergents, lubricants, and as a raw material in various chemical processes.

Tall Oil Rosin (TOR)

Tall oil rosin is another important derivative of tall oil. It is produced by distilling tall oil and is used in the formulation of adhesives, sealants, inks, and coatings. TOR enhances the tackiness and adhesive properties of these products.

Tall Oil Pitch

This is a byproduct obtained during the tall oil production process. It is a dark, viscous substance and may be used in applications such as road construction or as a binder in certain products.

Tall Oil Soap

Tall oil can be converted into tall oil soap, which is used as a collector in the flotation process in the mining industry to separate valuable minerals from ore.

Tall Oil Derivatives for Biofuels

Tall oil can be processed into biodiesel or renewable diesel, which can serve as alternative fuels.

Tall Oil Distillates

Tall oil distillates are fractions obtained during the distillation of tall oil. These fractions can have specific applications in various industries, including rubber processing and cosmetics.

Tall Oil Sterols

Tall oil contains sterols, which are used in the pharmaceutical and cosmetic industries for their potential health and skincare benefits.

Tall Oil Derivatives for Emulsifiers

Some tall oil derivatives are used as emulsifiers in products like emulsion paints and in various industrial processes.

Tall Oil Derivatives for Lubricants

Tall oil-based derivatives can be used as additives in lubricants to improve their performance, particularly in metalworking applications.

Tall Oil Derivatives for Paper Sizing

Tall oil fatty acids are used in the paper industry as sizing agents to enhance the water resistance and printability of paper products.

The specific types and derivatives of tall oil can vary depending on the processing methods and the intended applications. Producers can tailor the processing of tall oil to meet the requirements of different industries, resulting in a versatile range of products with various properties and applications.

How is Tall Oil produced

Tall oil is produced as a co-product of the kraft pulping process, which is commonly used in the paper and pulp industry. Here is an overview of how tall oil is produced:

Wood Preparation

The process begins with the preparation of wood, usually from coniferous trees like pine. The wood is debarked and chipped into small pieces.

Cooking

The wood chips are then subjected to a chemical cooking process in a digester. In kraft pulping, a mixture of water and chemicals, such as sodium hydroxide (caustic soda) and sodium sulfide, is used. The cooking process breaks down the wood fibers, separating the cellulose from lignin, which is a complex polymer that makes up a significant portion of wood.

Pulping

After cooking, the resulting pulp consists of cellulose fibers, residual lignin, and other components. The pulp is then washed and screened to remove impurities.

Tall Oil Formation

During the kraft pulping process, the lignin in the wood is degraded and transformed. Some of the lignin is released as soluble components, including tall oil. These soluble components are separated from the pulp mixture.

Separation

The tall oil and other soluble components are typically separated from the pulping liquor in a tall oil recovery system. This separation process may involve various stages, such as centrifugation or fractional distillation, to obtain the desired components, including tall oil.

Further Processing

The tall oil obtained in the recovery process can be further processed to extract specific components like tall oil fatty acids (TOFA) and tall oil rosin (TOR). These components have various industrial applications.

Remaining Pulp Processing

The remaining pulp, which is now lignin-free, can be further processed to produce paper or other cellulose-based products.

The exact details of the tall oil production process may vary depending on the specific equipment and technologies used by pulp and paper mills. Tall oil is considered a valuable co-product in the pulp and paper industry and has a range of industrial applications beyond paper production.

What drives the cost of Tall Oil

The cost of tall oil can be influenced by various factors, including supply and demand dynamics, production processes, and market conditions. Here are some key factors that can drive the cost of tall oil:

Raw Material Availability

The availability and cost of the raw material, which is typically wood from coniferous trees like pine, can significantly impact the cost of tall oil. Fluctuations in wood prices and the sustainability of forestry practices can influence raw material costs.

Pulp and Paper Industry

Tall oil is a co-product of the kraft pulping process used in the paper and pulp industry. Therefore, changes in the demand for paper and pulp products can indirectly affect tall oil production and pricing.

Production Efficiency

The efficiency of the tall oil recovery process at pulp and paper mills can affect the overall cost of tall oil. Improved recovery methods can lead to higher yields and lower production costs.

Market Demand

The demand for tall oil and its derivatives in various industries, such as soap and detergent manufacturing, adhesives, and biofuels, can influence prices. Strong demand can put upward pressure on prices.

Crude Oil Prices

Tall oil derivatives, particularly tall oil fatty acids (TOFA), are sometimes used as substitutes for petrochemical-based products. Changes in crude oil prices can impact the competitiveness of tall oil derivatives in the market.

Technological Advances

Advances in tall oil processing technologies can lead to more efficient production methods, potentially reducing production costs.

Environmental Regulations

Environmental regulations can impact the production processes and waste management practices in the pulp and paper industry, which in turn can influence the cost of tall oil production.

Transportation Costs

The cost of transporting tall oil and its derivatives to various markets can affect pricing, especially if the production facility is located far from key markets.

Currency Exchange Rates

Fluctuations in currency exchange rates can influence the cost of exporting or importing tall oil and its derivatives, particularly in the global market.

Market Competition

The presence of multiple suppliers and competition among manufacturers of tall oil and its derivatives can affect pricing as companies adjust prices to remain competitive.

It’s important to note that the cost of tall oil can vary over time and across regions due to these factors. Producers and buyers of tall oil and its derivatives need to consider these variables when assessing pricing and market conditions. Additionally, market conditions and economic factors can also impact the cost of tall oil-related products in specific industries and applications

Which countries produce the most Tall Oil

The production of tall oil is closely tied to the pulp and paper industry, and the countries with significant pulp and paper production tend to be the largest producers of tall oil. Some of the countries that historically produced the most tall oil include:

United States

The United States, particularly in regions with a strong pulp and paper industry like the Southern and Pacific Northwest regions, is one of the leading producers of tall oil.

Sweden

Sweden has a well-established pulp and paper industry, and tall oil production is significant in the country.

Finland

Finland, like Sweden, has a robust forest industry, and tall oil is produced as a byproduct of pulp and paper manufacturing.

Canada

Canada, with its extensive forests and pulp and paper industry, is another significant producer of tall oil.

Brazil

Brazil’s pulp and paper industry has been growing, and it also contributes to tall oil production.

Norway

Norway, with its forestry and paper production activities, is a notable tall oil producer.

Russia

Russia has a significant pulp and paper industry, and tall oil production is part of the byproducts generated in this sector.

Chile

Chile’s forestry sector contributes to tall oil production, although it may be a smaller producer compared to some other countries.

Please note that the specific rankings and production volumes can change over time due to market dynamics, changes in the pulp and paper industry, and other factors. To obtain the most up-to-date information on tall oil production by country, it is advisable to refer to industry reports, government statistics, and trade associations in the pulp and paper sector

TOFA market information

The global tall oil market is a niche market within the broader chemical and forestry industries. Its size can fluctuate based on various factors such as the demand for pulp and paper products, the use of tall oil derivatives in various industrial applications, and regional economic conditions. Generally, the global tall oil market was estimated to be in the range of hundreds of millions to a few billion US dollars in terms of annual revenue.

It’s worth noting that tall oil and its derivatives have a range of applications, including in the production of soaps, adhesives, biofuels, and more. The market size may vary by region, with regions heavily involved in the pulp and paper industry, such as North America and Europe, having a significant share of the market.

According to https://oec.world/ :

Tall oil fatty acids are the world’s 3417th most traded product.

In 2020, the top exporters of Tall oil fatty acids were United States ($68M), Finland ($63.9M), Sweden ($39.7M), Netherlands ($25.7M), and France ($20.2M).

In 2020, the top importers of Tall oil fatty acids were Netherlands ($19.9M), Germany ($15.9M), Sweden ($14.8M), Russia ($13.5M), and France ($13M).

Further information

Business Analytiq

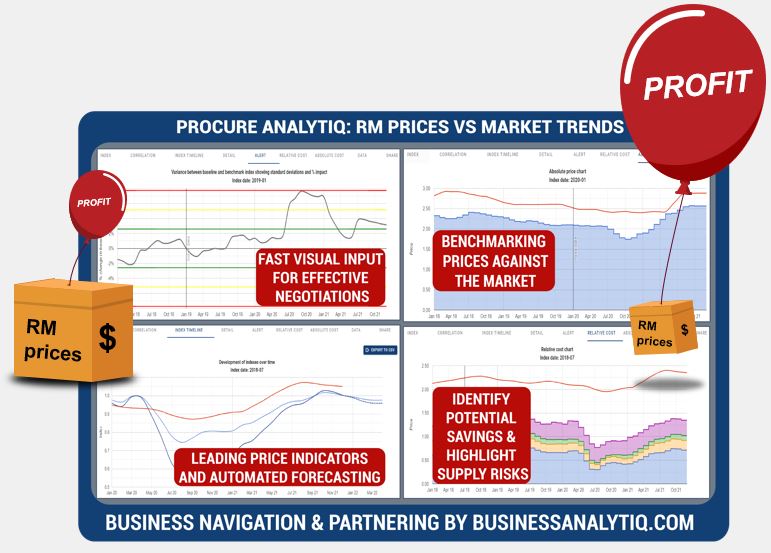

BE THE FIRST TO SEE RISK AND OPPORTUNITY!

BusinessAnalytiq provides unlimited market trend data and an online tools to track market developments, key benchmarks & leading indicators.

BusinessAnalytiq leads to price visibility, better negotiations, easier budgeting and forecasting, lower raw material prices, and improved better internal and external communication. BusinessAnalytiq will decrease risk and higher profit.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page