Praseodymium neodymium price November 2024 and outlook (see chart below)

- Northeast Asia:US$80.3/KG, 0.4% up

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Praseodymium neodymium price index

This post is a summary of the Praseodymium neodymium price developments. The price developments of Praseodymium neodymium are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Praseodymium neodymium price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Praseodymium neodymium prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of Praseodymium neodymium prices

- Recent price developments of underlying feedstocks which drive the price of Praseodymium neodymium

- Market futures for both cost drives and feedstocks of Praseodymium neodymium prices

- Adjustment of current supply/demand imbalances in the Praseodymium neodymium market

- Longer term trends in likely demand conditions

Further information on the Praseodymium-neodymium price index

What is Praseodymium-neodymium

Praseodymium-neodymium (Pr-Nd) is a rare earth alloy that typically contains both praseodymium (Pr) and neodymium (Nd) in varying proportions. Rare earth alloys, such as Pr-Nd, are commonly used in the manufacturing of high-strength permanent magnets, particularly in neodymium-based magnets (NdFeB).

The combination of praseodymium and neodymium in these magnets provides several advantages:

Enhanced Magnetic Properties

Neodymium contributes significantly to the magnet’s overall magnetic strength due to its strong magnetic properties. Praseodymium enhances the magnetic properties and stability of the magnet when combined with neodymium.

Improved Temperature Stability

Praseodymium can improve the temperature stability of neodymium-based magnets. This is important in applications where the magnets are exposed to high temperatures, as it helps maintain their magnetic properties over a wider temperature range.

Reduced Rare Earth Content

By incorporating praseodymium into the alloy, manufacturers can reduce the overall neodymium content in the magnet. This can help mitigate supply chain challenges associated with neodymium’s scarcity and fluctuating prices.

Praseodymium-neodymium magnets, often referred to as Pr-Nd magnets, are widely used in various applications, including:

Electric Motors and Generators

Pr-Nd magnets are commonly used in electric motors and generators found in electric vehicles, wind turbines, industrial machinery, and household appliances.

Audio Equipment

Pr-Nd magnets are used in loudspeakers, headphones, and microphones to convert electrical energy into mechanical vibrations, producing sound.

Magnetic Separators

Pr-Nd magnets are utilized in magnetic separation equipment to separate and purify materials in industries such as mining, recycling, and food processing.

MRI Machines

Pr-Nd magnets are used in magnetic resonance imaging (MRI) machines for medical diagnostics. These magnets provide the strong magnetic fields necessary for imaging soft tissues and organs in the human body.

Overall, Praseodymium-neodymium alloys play a crucial role in modern technology, particularly in applications requiring strong and stable magnetic properties.

How is Praseodymium-neodymium produced

Praseodymium-neodymium (Pr-Nd) alloy is typically produced through a process known as metallothermic reduction, which involves the reduction of praseodymium and neodymium oxides with a reducing agent, often magnesium or calcium. Here’s an overview of the production process:

Raw Material Preparation

The raw materials used in the production of Pr-Nd alloy are typically praseodymium oxide (Pr2O3) and neodymium oxide (Nd2O3). These oxides are usually obtained from the processing of rare earth ores, such as monazite or bastnasite.

Mixing and Blending

Praseodymium oxide and neodymium oxide are mixed together in the desired proportions to achieve the desired composition of the alloy. The oxides may also be mixed with a reducing agent, such as magnesium or calcium, which will facilitate the reduction reaction.

Reduction Reaction

The mixed powders are then subjected to a high-temperature reduction reaction in a controlled environment, typically in a vacuum or inert gas atmosphere. During the reduction reaction, the oxygen atoms from the oxides are removed, and the praseodymium and neodymium metals are formed. The reducing agent, such as magnesium or calcium, reacts with the oxygen to form magnesium oxide or calcium oxide, which is removed as a slag.

Separation and Purification

After the reduction reaction, the alloy is separated from the slag and any remaining impurities. The alloy may undergo further purification steps, such as refining by vacuum distillation or zone melting, to remove any remaining impurities and achieve the desired composition and purity.

Forming and Solidification

The purified Pr-Nd alloy is then formed into the desired shape, typically through casting, rolling, or extrusion processes. The alloy may also be further processed through heat treatment to optimize its microstructure and properties.

Final Processing

The Pr-Nd alloy may undergo additional processing steps, such as machining, surface treatment, or coating, depending on the specific application requirements.

Overall, the production of Pr-Nd alloy involves a combination of chemical reactions, separation processes, and metalworking techniques to obtain the desired composition, purity, and properties of the alloy for various industrial applications, particularly in the manufacturing of high-strength permanent magnets.

What is Praseodymium-neodymium used for

Praseodymium-neodymium (Pr-Nd) alloy, commonly known as NdPr alloy, is primarily used in the manufacturing of high-strength permanent magnets, particularly in neodymium-based magnets (NdFeB). These magnets are crucial components in various modern technologies and applications due to their exceptional magnetic properties. Here are some key uses of Pr-Nd alloy:

Electric Vehicles (EVs) and Hybrid Vehicles

NdFeB magnets made with Pr-Nd alloy are essential components in electric motors and generators used in electric vehicles (EVs) and hybrid vehicles. These magnets contribute to the efficiency, power, and torque of the motors, enabling high-performance and energy-efficient propulsion systems.

Wind Turbines

NdFeB magnets containing Pr-Nd alloy are employed in the generators of wind turbines to convert mechanical energy from the wind into electrical energy. The use of high-strength magnets helps optimize the efficiency and reliability of wind power generation systems.

Consumer Electronics

Pr-Nd alloy-based magnets are extensively used in consumer electronics, including smartphones, laptops, headphones, and speakers. These magnets play critical roles in various components such as vibration motors, speakers, microphones, and hard disk drives, enhancing performance and miniaturization in electronic devices.

Industrial Machinery

NdFeB magnets made with Pr-Nd alloy are utilized in industrial machinery and equipment for various purposes, including magnetic separators, actuators, sensors, and lifting devices. These magnets provide strong and reliable magnetic fields, improving efficiency and precision in industrial processes.

Medical Devices

NdFeB magnets containing Pr-Nd alloy are used in medical devices and equipment, including magnetic resonance imaging (MRI) machines and medical sensors. The high magnetic field strength and stability of these magnets are crucial for high-resolution imaging and diagnostic applications in healthcare.

Energy Storage Systems

NdFeB magnets made with Pr-Nd alloy are also employed in energy storage systems, such as magnetic bearings and magnetic levitation systems. These magnets enable frictionless motion and precise control in various mechanical and electromechanical systems.

Aerospace and Defense

Pr-Nd alloy-based magnets are utilized in aerospace and defense applications, including aircraft components, missile guidance systems, radar systems, and magnetic shielding. These magnets provide lightweight, compact, and reliable solutions for critical systems and equipment.

Overall, Praseodymium-neodymium alloy plays a vital role in enabling advanced technologies across diverse industries, providing essential magnetic properties for a wide range of applications, including transportation, renewable energy, electronics, healthcare, manufacturing, and defense.

How big is the global Praseodymium-neodymium market

The main rare earth elements ranked in decreasing order of market size are:

Neodymium (Nd): Neodymium is often ranked as one of the most valuable rare earth elements due to its crucial role in the production of high-strength permanent magnets used in a wide range of applications, including electric vehicle motors and wind turbines.

Cerium (Ce): Cerium is among the most abundant rare earth elements and is used in various industrial applications, such as catalysts, glass polishing, and metallurgy.

Lanthanum (La): Lanthanum is used in catalysts, ceramics, optics, and as a component in certain types of batteries and fuel cells.

Dysprosium (Dy): Dysprosium is used to improve the high-temperature performance of neodymium-iron-boron magnets. It is essential for the growth of the clean energy and electric vehicle markets.

Praseodymium (Pr): Praseodymium is used in combination with neodymium to produce high-strength magnets. It is vital in the manufacture of electric vehicle motors and wind turbines.

Europium (Eu): Europium is primarily used in phosphors for color television tubes, LED lighting, and other display technologies.

Terbium (Tb): Terbium is used in phosphors for color television tubes, fluorescent lamps, and as an activator for green phosphors.

Yttrium (Y): Yttrium is not a lanthanide, but it is often grouped with rare earth elements. It is used in a variety of applications, including ceramics, superconductors, and phosphors.

It’s important to note that market rankings may change over time as new technologies and applications emerge and as supply and demand conditions evolve. The demand for rare earth elements is influenced by various industries, including electronics, automotive, renewable energy, and more. For the most current market information and rankings, it’s advisable to consult industry reports and market analysis from reputable sources

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

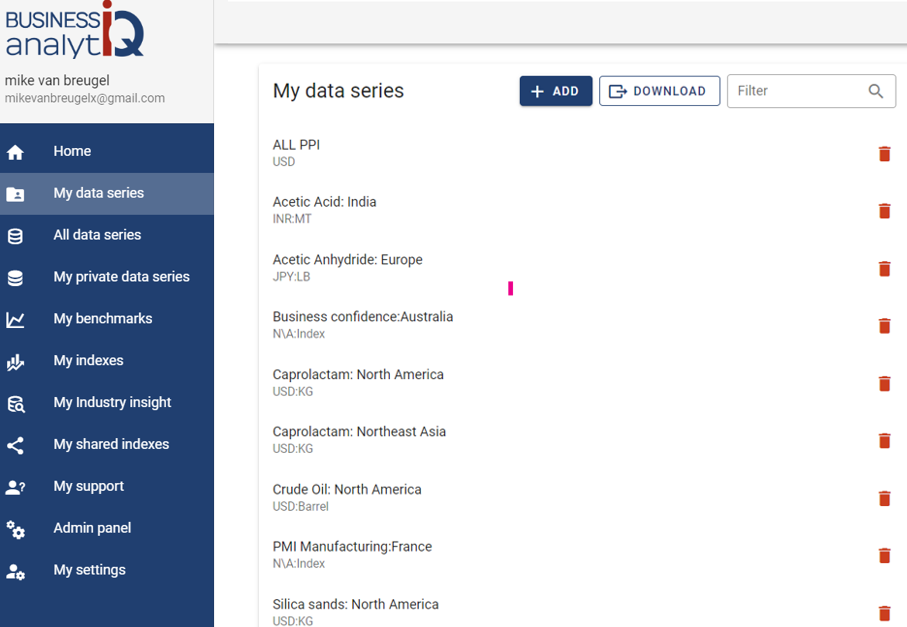

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page