Aluminum fluoride price February 2025 and outlook (see chart below)

- Northeast Asia:US$1.77/KG, -3.3% down

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

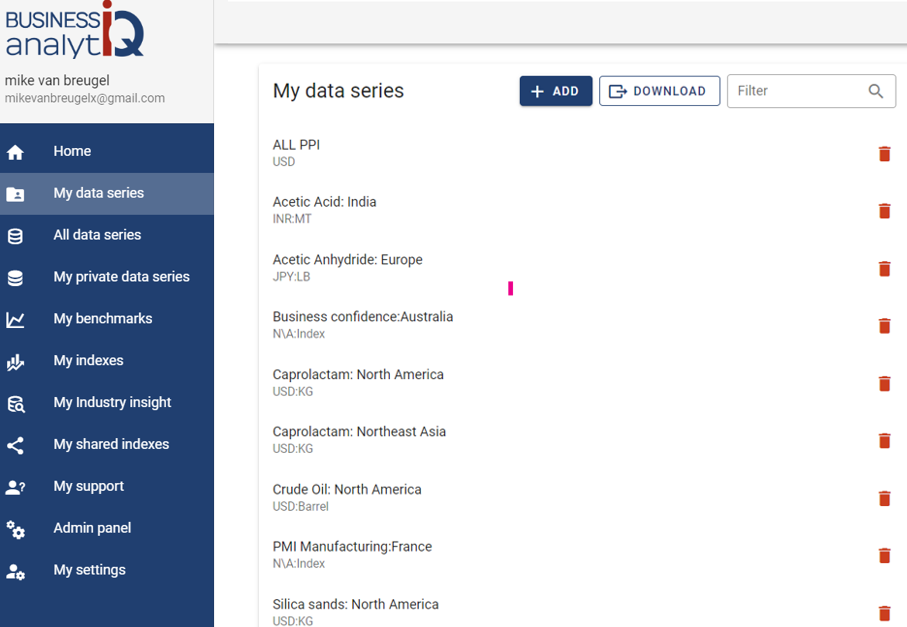

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Aluminum fluoride price index

This post is a summary of the Aluminum fluoride price developments. The price developments of Aluminum fluoride are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Aluminum fluoride price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Aluminum fluoride prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of Aluminum fluoride prices

- Recent price developments of underlying feedstocks which drive the price of Aluminum fluoride

- Market futures for both cost drives and feedstocks of Aluminum fluoride prices

- Adjustment of current supply/demand imbalances in the Aluminum fluoride market

- Longer term trends in likely demand conditions

Further information on the Aluminum fluoride price chart

What is Aluminum fluoride

Aluminum fluoride (AlF₃) is an important industrial chemical with a variety of applications, particularly in the production of aluminum metal and in the ceramics industry. Below is a comprehensive overview covering its definition, production methods, applications, and key properties.

Aluminum fluoride (AlF₃) is an inorganic compound composed of aluminum and fluorine. It is typically encountered as a white or colorless solid and exists in several crystalline forms, the most common being the α, β, and γ polymorphs. Aluminum fluoride is primarily used as a flux in the production of aluminum metal, where it lowers the melting point of alumina (Al₂O₃) and facilitates the electrolysis process.

How is Aluminum fluoride produced

Aluminum fluoride is produced through various chemical processes, primarily involving the reaction of aluminum-containing compounds with fluorine sources. The main production methods include:

Reaction with Hydrofluoric Acid (HF)

This is the most common industrial method for producing AlF₃.

Process Steps:

Starting Material

Aluminum hydroxide (Al(OH)₃) or aluminum oxide (Al₂O₃) is reacted with hydrofluoric acid.

Reaction

The reaction proceeds under controlled conditions to produce aluminum fluoride and water.

Purification

The resulting AlF₃ is purified by removing impurities through recrystallization or other separation techniques.

Direct Reaction with Fluorine Gas (F₂)

While less common due to safety and handling concerns associated with fluorine gas, aluminum fluoride can also be synthesized by directly reacting aluminum with fluorine.

Process Considerations:

Safety

Handling fluorine gas requires stringent safety measures due to its highly reactive and toxic nature.

Conditions

The reaction is typically carried out at elevated temperatures to facilitate the formation of AlF₃.

Thermal Decomposition

Aluminum fluoride can also be produced by the thermal decomposition of aluminum complexes or salts containing fluoride ions.

Process Steps

Starting Material

Aluminum complexes such as aluminum trifluoride ethoxide.

Heating

The compound is heated to decompose into AlF₃ and ethanol.

What is Aluminum fluoride used for

Aluminum fluoride has a wide range of applications across various industries due to its properties as a flux, catalyst, and intermediate compound. The primary uses include:

Production of Aluminum Metal

Role as a Flux: AlF₃ is a critical component of the electrolytic cells used in the Hall-Héroult process for aluminum production. It lowers the melting point of alumina, reducing energy consumption and improving the efficiency of the electrolysis.

Cryolite Replacement: Although cryolite (Na₃AlF₆) is traditionally used, aluminum fluoride is often added to enhance the properties of the electrolyte.

Ceramics and Glass Manufacturing

Flux in Glazes and Vitrification: AlF₃ acts as a flux in ceramic glazes, helping to lower the melting temperature and improve the surface finish.

Glass Additive: It is used in the production of certain types of glass to modify properties such as thermal expansion and chemical durability.

Catalysis

Catalyst in Organic Reactions: AlF₃ serves as a Lewis acid catalyst in various organic synthesis reactions, including alkylation and polymerization processes.

Petroleum Refining: It is employed as a catalyst in the alkylation units of petroleum refineries to produce high-octane gasoline components.

Metallurgy

Flux for Metal Refining: Beyond aluminum production, AlF₃ is used as a flux in the refining of other metals, aiding in the removal of impurities and facilitating smelting processes.

Other Applications

Pharmaceuticals: Used in certain pharmaceutical formulations and as a reagent in chemical synthesis.

Electronics: Utilized in the manufacturing of electronic components and as a precursor for other fluorine-containing compounds.

What are the key characteristics of Aluminum fluoride

Physical Properties

Appearance: White or colorless crystalline solid.

Melting Point: Approximately 1298 °C (2370 °F)

Boiling Point: Decomposes before reaching a boiling point.

Density: About 2.54 g/cm³ at 25 °C

Solubility: Insoluble in water; however, it reacts with water to form hydrofluoric acid and aluminum hydroxide:

Safety and Handling

Toxicity: Aluminum fluoride is hazardous if inhaled, ingested, or comes into contact with skin and eyes. It can cause irritation and burns.

Handling Precautions:

Personal Protective Equipment (PPE): Use appropriate PPE, including gloves, goggles, and protective clothing.

Ventilation: Ensure adequate ventilation to avoid inhalation of dust or fumes.

Storage: Store in a cool, dry place away from moisture and incompatible materials like strong acids or bases.

Thermal Properties

Heat Capacity: Exhibits high thermal stability, making it suitable for high-temperature applications such as in the aluminum smelting process.

Thermal Conductivity: Moderate thermal conductivity, facilitating its role as a flux.

Crystallography

Crystal Structure: AlF₃ adopts a cubic structure in its α-form, which is the most stable and commonly encountered polymorph.

Polymorphism: Exists in multiple polymorphic forms (α, β, γ), each with distinct crystal structures and properties.

How big is the global Aluminum fluoride market

As of 2023, the global aluminum fluoride market was estimated to be valued at approximately USD 800 million to USD 1 billion. This valuation reflects the market’s steady demand across various applications, particularly in the aluminum production sector.

Growth Trends and Forecast

Historical Growth

2018-2022: The market experienced a compound annual growth rate (CAGR) of around 4-5%, driven by increasing aluminum production and expanding applications in ceramics and glass manufacturing.

Projected Growth

2023-2028: The aluminum fluoride market is anticipated to grow at a CAGR of approximately 5-6%, reaching an estimated value of USD 1.2 billion to USD 1.3 billion by 2028.

Key Market Drivers

Aluminum Production Expansion

Hall-Héroult Process: Aluminum fluoride is essential as a flux in the electrolytic production of aluminum. Growth in the aluminum industry directly propels the demand for AlF₃.

Infrastructure Development: Increasing infrastructure projects globally, especially in emerging economies, are boosting aluminum demand.

Growth in Ceramics and Glass Manufacturing

Ceramic Glazes: AlF₃ is used to lower the melting temperature of ceramic glazes, enhancing production efficiency.

Specialty Glass: Utilized in the production of high-quality glass with specific thermal and chemical properties.

Catalysis and Chemical Synthesis Applications

Petroleum Refining: AlF₃ serves as a catalyst in alkylation processes to produce high-octane gasoline components.

Organic Synthesis: Acts as a Lewis acid catalyst in various chemical reactions.

Technological Advancements

Process Optimization: Innovations in aluminum smelting and refining processes enhance the efficiency and reduce the environmental impact, increasing AlF₃ utilization.