Bronze price April 2024 and outlook (see chart below)

- Europe:US$12.32/KG, 2.4% up

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, fitness for purpose or timeliness.

Bronze Price Index

This post is a summary of the Bronze price developments. The price developments of Bronze are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Bronze price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Bronze prices is generated from different inputs including:

- Very recent price developments of immediate cost drivers of Bronze prices

- Recent price developments of underlying feedstocks which drive the price of Bronze

- Market futures for both cost drives and feedstocks of Bronze prices

- Adjustment of current supply/demand imbalances in the Bronze market

- Longer term trends in likely demand conditions

Further sources of information on the Bronze price chart

What is Bronze

Bronze is a metal alloy primarily composed of copper and tin, although it can also contain other elements like aluminum, silicon, and phosphorus in varying proportions. The exact composition of bronze can vary depending on its intended use and the desired properties. Bronze is known for its historical significance and a wide range of applications due to its unique combination of properties, including:

Durability

Bronze is a durable material that can withstand corrosion and wear over time. It is often used in applications that require longevity and resistance to the elements.

Strength

Bronze is stronger than pure copper and is often used for structural components and tools.

Malleability

Like copper, bronze is malleable and can be easily shaped and formed into various shapes and objects.

High Melting Point

Bronze has a higher melting point than copper, making it suitable for applications that involve exposure to high temperatures.

Corrosion Resistance

Bronze is less susceptible to corrosion than iron or steel, making it a suitable choice for marine and outdoor applications.

Aesthetic Appeal

Bronze has a distinctive reddish-brown color that can develop a beautiful patina over time, giving it an attractive and classic appearance.

How is Bronze produced

Bronze is produced through a metallurgical process called alloying, where copper and tin (or other elements) are combined to create the bronze alloy. The production of bronze involves several steps:

Raw Materials

The primary raw materials used in bronze production are copper and tin. Copper is typically obtained from copper ore, while tin is usually obtained from tin ore. These ores are mined from the earth.

Ore Processing

The copper and tin ores are first processed to extract the respective metals. Copper is typically extracted through a process called smelting, while tin is obtained through various methods, including roasting and reduction.

Alloying

Once copper and tin are obtained in their metal forms, they are combined in the desired proportions to create the bronze alloy. The exact ratio of copper to tin can vary depending on the specific type of bronze being produced and its intended use. Historically, many bronze alloys contained approximately 90% copper and 10% tin, but variations exist.

Melting

The copper and tin are then melted together in a furnace. The temperature required for melting bronze can vary based on the specific alloy composition but is typically around 1,100 to 1,200 degrees Celsius (2,012 to 2,192 degrees Fahrenheit).

Alloy Homogenization

After melting, the molten bronze is often stirred to ensure that the copper and tin are thoroughly mixed, creating a uniform alloy. This step is essential for achieving consistent properties throughout the material.

Casting

The molten bronze is poured into molds to create specific shapes or forms. These molds can vary in size and shape depending on the intended final product. The bronze cools and solidifies within the molds.

Cooling and Solidification

The bronze cools and solidifies within the molds. Once it has solidified, the cast bronze parts are removed from the molds.

Finishing

The cast bronze parts may undergo additional processes such as machining, polishing, or patination (to create a desired surface appearance) to achieve the desired final finish and dimensions.

Quality Control

Quality control measures are taken to ensure that the bronze meets the required specifications and standards. This may include testing for mechanical properties, chemical composition, and surface finish.

Final Applications

The finished bronze products are then used in various applications based on their intended purpose, such as sculptures, musical instruments, bearings, marine hardware, and more.

It’s important to note that while copper and tin are the most common components of bronze, other elements like aluminum, silicon, phosphorus, or zinc can be added in small amounts to achieve specific properties or enhance certain characteristics of the alloy. The choice of alloy composition and production methods can vary based on the desired properties and the intended use of the bronze.

What is Bronze used for

Historically, bronze has been used for a wide range of purposes, including the production of sculptures, coins, tools, weapons, and architectural elements. The Bronze Age, which occurred around 3300 to 1200 BCE, is named after the widespread use of bronze in that era.

Today, bronze is still used in various applications, including:

Statuary and Sculptures

Bronze is a popular material for creating sculptures and statues due to its aesthetic appeal and durability.

Musical Instruments

Some musical instruments, such as bells and cymbals, are made from bronze alloys because of their resonant qualities.

Bearings and Bushings

Bronze is used in the manufacture of bearings and bushings for machinery and equipment due to its low friction characteristics.

Coins and Medals

Bronze or bronze alloys are occasionally used for coins and commemorative medals.

Marine Hardware

Due to its resistance to corrosion, bronze is used in marine applications like boat fittings and propellers.

Valves and Fittings

Bronze valves and fittings are used in plumbing and fluid control systems.

Antiques and Decorative Items

Antique bronze items and decorative objects continue to be valued for their historical significance and aesthetic appeal.

Bronze alloys can vary in composition to achieve specific properties, such as phosphor bronze and aluminum bronze, each offering unique advantages for different applications

Business Analytiq

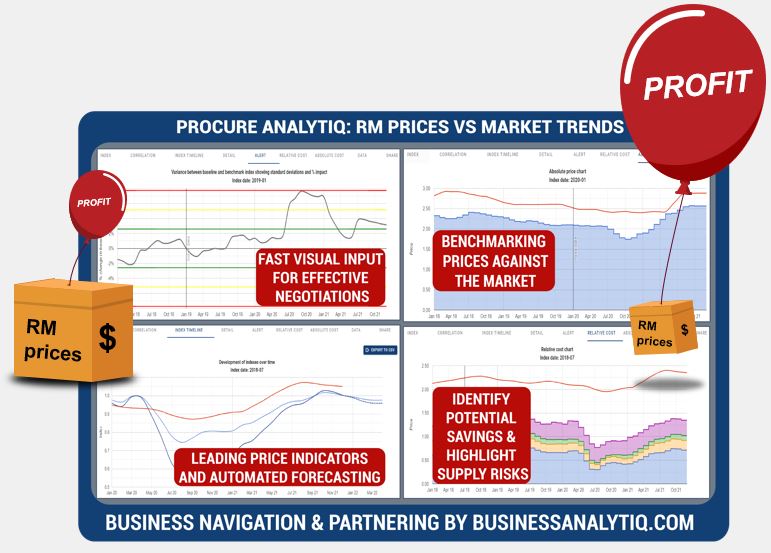

BE THE FIRST TO SEE RISK AND OPPORTUNITY!

BusinessAnalytiq provides unlimited market trend data and an online tools to track market developments, key benchmarks & leading indicators.

BusinessAnalytiq leads to price visibility, better negotiations, easier budgeting and forecasting, lower raw material prices, and improved better internal and external communication. BusinessAnalytiq will decrease risk and higher profit.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page