Summary of recent glass cullet price developments

- North America:US$116.51/KG, -1.7% down

- Europe:US$77.67/KG, -1.3% down

- Northeast Asia:US$95.68/MT, -2.3% down

The chart below shows the recent glass cullet price developments and the outlook. It takes a moment to load.

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Glass cullet price index

This post is a summary of the glass cullet price developments. The price developments of glass cullet are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Glass cullet price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook of glass cullet prices is generated from different inputs including:

- Very recent price developments of immediate cost drivers of glass cullet prices

- Recent price developments of underlying feedstocks which drive the price of glass cullet

- Market futures for both cost drives and feedstocks of glass cullet prices

- Adjustment of current supply/demand imbalances in the glass cullet market

- Longer term trends in likely demand conditions

Further information on the glass cullet price chart

What is glass cullet

Cullet refers to crushed or broken glass that is recycled and used in the manufacturing of new glass products. When glass containers, bottles, or other glass items are collected for recycling, they are sorted, cleaned, and crushed into small pieces. These crushed glass pieces are called cullet.

What is glass cullet used for

Glass cullet is used primarily in the manufacturing of new glass products. When recycled glass is crushed into cullet, it can be mixed with raw materials and melted to create various types of glass products. Some common uses of glass cullet include:

New glass containers

Cullet is often used to produce new glass bottles, jars, and other containers used for packaging food and beverages.

Fiberglass

Cullet can be used in the production of fiberglass, a material used in insulation, textiles, and composites.

Glass tiles and countertops

Cullet is incorporated into the manufacturing of glass tiles and countertops used in interior design and architecture.

Glassware

Cullet is used to create new glassware, such as drinking glasses, vases, and decorative items.

Insulation materials

Glass cullet can be used in the production of insulating materials for buildings and vehicles.

Fiberglass reinforced plastics (FRP)

Cullet is also used in the production of FRP, which finds applications in various industries, including automotive and aerospace.

Glassphalt

In some cases, cullet is used in the construction industry to create “glassphalt,” an asphalt mix that contains recycled glass particles, which can improve the road surface’s durability.

Water filtration media

Crushed glass cullet is used as a filtration media in water treatment systems to remove impurities from water.

Using cullet in these applications provides environmental benefits, such as reduced energy consumption and the conservation of natural resources, making it a sustainable choice for glass manufacturers and consumers alike.

What types of cullet are there

Glass cullet can be categorized based on various characteristics, including color, size, and source. Here are some common types of glass cullet:

Clear Cullet

Clear glass cullet comes from transparent glass containers like clear bottles and jars. It is widely used in the manufacturing of new clear glass products.

Green Cullet

Green glass cullet originates from green-colored glass containers, such as beer and wine bottles. It is commonly used to produce new green glass items.

Brown or Amber Cullet

This type of cullet comes from brown or amber glass containers, like beer bottles and some food jars. It is used to create new brown glass products.

Mixed Cullet

Mixed cullet is a combination of various colors of crushed glass. It may include clear, green, brown, and other glass types. Mixed cullet is versatile and can be used to create various colored glass products or be further sorted into specific colors.

Flint Cullet

Flint glass cullet refers to clear, high-quality glass without any impurities. It is often used in the production of premium glass products, such as fine glassware and optical lenses.

Post-Consumer Cullet

Post-consumer cullet comes from recycled glass containers that have been used and collected from households and businesses. Recycling post-consumer glass reduces waste and conserves resources.

Pre-Consumer Cullet

Pre-consumer cullet, also known as “factory cullet,” comes from glass manufacturing scraps and rejects that were never used by consumers. Recycling pre-consumer cullet helps reduce waste during the manufacturing process.

Specialty Cullet

Some glass cullet may be classified as specialty cullet, which includes specific types of glass, such as borosilicate glass used in laboratory equipment or certain glass compositions used for specific industrial applications.

The classification of cullet types helps glass manufacturers effectively sort and recycle glass, ensuring that the right cullet is used for specific glass products. Recycling different types of glass cullet is an essential part of sustainable glass production and waste management practices.

How is glass cullet produced

The production of glass cullet involves several steps, starting from the collection of glass waste to the crushing and processing of the glass. Here’s a general overview of how glass cullet is produced:

Collection

The process begins with the collection of used glass items such as bottles, jars, and other glass containers. These items are collected from recycling bins, drop-off points, or curbside recycling programs.

Sorting

Once collected, the glass is transported to a recycling facility where it undergoes sorting. At the facility, the glass is separated by color (clear, green, brown, etc.) to ensure that the cullet produced is of high quality and suitable for specific glass products.

Cleaning

After sorting, the glass is thoroughly cleaned to remove any contaminants, such as labels, caps, and other non-glass materials. The cleaning process helps ensure that the cullet is free from impurities that could negatively impact the quality of the new glass products.

Crushing

The cleaned glass is then fed into crushing machines, which break the glass into small pieces. The size of the cullet can vary depending on the intended use. Typically, the glass is crushed into small fragments, similar to the size of gravel.

Magnetic Separation

After crushing, the cullet is passed through magnetic separators to remove any ferrous materials like metal caps and lids that might have been missed during the cleaning process.

Density Separation

Some recycling facilities may use density separation techniques to remove non-glass materials like plastic and paper that may still be present in the cullet.

Quality Control

The processed cullet is inspected for quality, ensuring that it meets the required standards for color, size, and cleanliness. Any substandard cullet may be removed or reprocessed.

Storage

The final cullet is stored in large containers or silos until it is ready to be used in glass manufacturing.

Glass Manufacturing: Glass manufacturers purchase the cullet and mix it with raw materials such as sand, soda ash, and limestone. This mixture is melted in furnaces to produce molten glass, which can then be shaped into new glass products, such as bottles, containers, glassware, and more.

The production of glass cullet is an essential step in the glass recycling process, as it helps conserve natural resources, reduce energy consumption, and minimize waste sent to landfills. Recycling glass into cullet promotes sustainability and is a crucial aspect of a circular economy.

What drives the price of cullet

The price of cullet, like any other commodity, is influenced by various factors in the market. Some of the key drivers of cullet prices include:

Demand and Supply

The fundamental law of supply and demand plays a significant role in determining the price of cullet. When the demand for cullet is high, but the supply is limited, prices tend to rise. Conversely, when there is an abundant supply of cullet and low demand, prices may decrease.

Glass Manufacturing Demand

The demand for cullet is closely tied to the needs of glass manufacturers. If glass manufacturers prefer to use more cullet in their production processes due to environmental and cost considerations, the demand for cullet increases, potentially leading to higher prices.

Virgin Raw Material Prices

The price of virgin raw materials used in glass production, such as sand, soda ash, and limestone, can also influence cullet prices. When the cost of virgin raw materials is high, glass manufacturers may seek to use more cullet as a cost-effective alternative, driving up the demand and price of cullet.

Transportation Costs

The cost of transporting cullet from recycling facilities to glass manufacturing plants can impact its price. Longer distances and higher transportation costs can contribute to higher cullet prices.

Quality of Cullet

The quality of cullet, including factors such as color, cleanliness, and size, can affect its price. High-quality cullet that requires minimal additional processing may command a higher price.

Recycling Infrastructure and Efficiency

The efficiency and sophistication of recycling facilities also play a role in cullet pricing. Advanced recycling processes that produce high-quality cullet with minimal contamination may be more cost-effective, potentially impacting prices.

Government Policies and Regulations

Government policies and regulations related to recycling, waste management, and environmental protection can influence the recycling rates and availability of cullet, consequently affecting its price.

Economic Conditions

The overall economic conditions in a region or country can also influence cullet prices. During economic downturns, there may be reduced demand for glass products, leading to lower demand for cullet and potentially lower prices.

It’s important to note that cullet prices can vary regionally and over time due to the dynamic nature of these influencing factors. Glass recycling and the use of cullet remain important strategies for sustainable waste management and resource conservation, and market conditions can shape their viability and cost-effectiveness.

How big is the global cullet market

The global cullet market size is estimated to be around 72 million metric tons per year. This figure represents the total annual production and usage of recycled glass cullet worldwide.

The cullet market has been growing steadily in response to increasing environmental concerns and the drive towards sustainable practices. Many countries have implemented recycling programs, and glass manufacturers are increasingly using cullet in their production processes to reduce energy consumption and raw material usage.

Which countries produce the most cullet

As of September 2021, the countries that produced the most cullet varied based on their recycling rates and the size of their glass manufacturing industries. Some of the leading cullet-producing countries included:

United States

The United States is one of the largest producers of cullet in the world due to its significant glass manufacturing sector and well-established recycling programs.

Germany

Germany has a strong commitment to recycling, and its glass recycling rates are among the highest globally, contributing to its significant cullet production.

Japan

Japan is known for its efficient waste management and recycling practices, including glass recycling, which contributes to its substantial cullet production.

Italy

Italy has a well-developed glass manufacturing industry and a strong focus on recycling, making it a significant producer of cullet.

France

France has implemented effective recycling programs, contributing to its notable cullet production.

United Kingdom

The UK has made significant efforts to improve glass recycling rates, leading to considerable cullet production.

Australia

Australia’s emphasis on recycling and environmental awareness has led to a significant cullet production.

China

China is a major player in the global glass industry and has been investing in glass recycling infrastructure, making it a notable cullet producer.

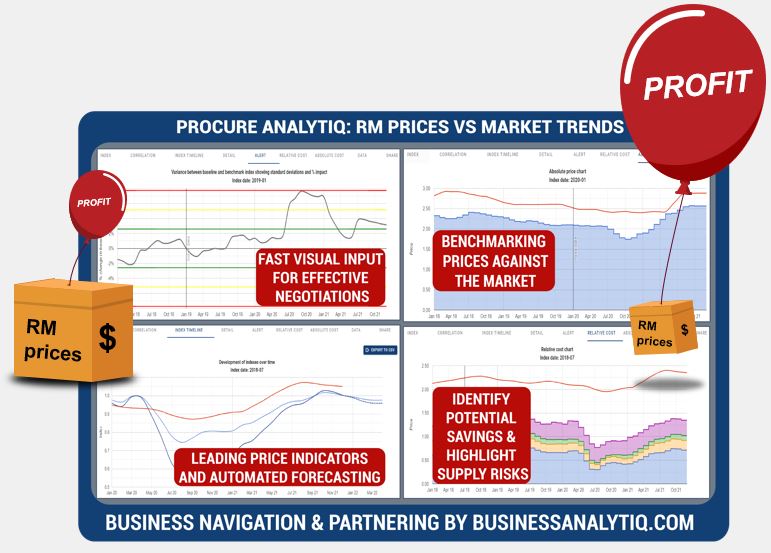

Business Analytiq

BE THE FIRST TO SEE RISK AND OPPORTUNITY!

BusinessAnalytiq provides unlimited market trend data and an online tools to track market developments, key benchmarks & leading indicators.

BusinessAnalytiq leads to price visibility, better negotiations, easier budgeting and forecasting, lower raw material prices, and improved better internal and external communication. BusinessAnalytiq will decrease risk and higher profit.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page