Cyclohexanol price February 2025 and outlook (see chart below)

- Northeast Asia:US$1.33/KG, -2.2% down

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

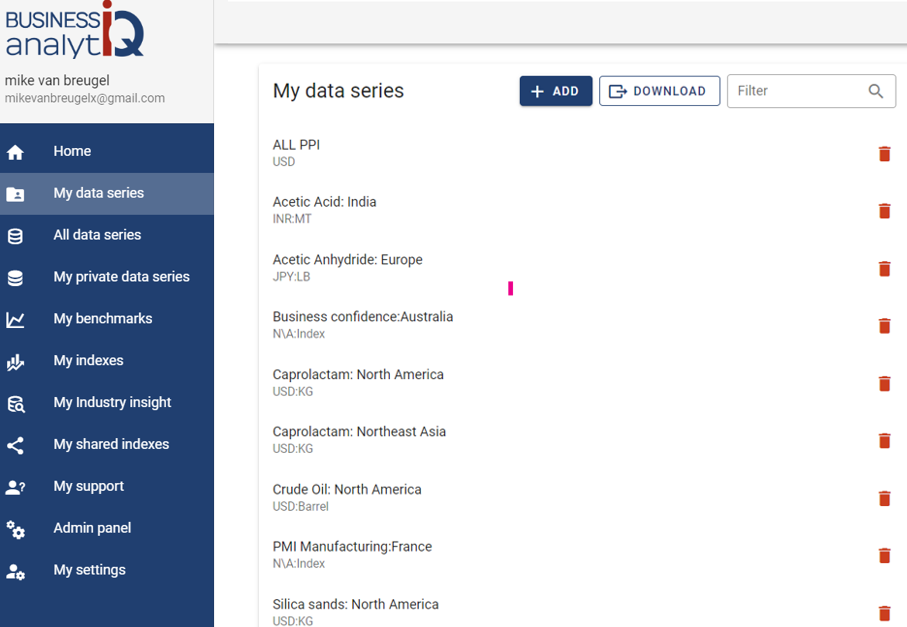

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Cyclohexanol price index

This post is a summary of the Cyclohexanol price developments. The price developments of Cyclohexanol are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Cyclohexanol price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Cyclohexanol prices is generated from different inputs including:

- Very recent price developments of immediate cost drivers of Cyclohexanol prices

- Recent price developments of underlying feedstocks which drive the price of Cyclohexanol

- Market futures for both cost drives and feedstocks of Cyclohexanol prices

- Adjustment of current supply/demand imbalances in the Cyclohexanol market

- Longer term trends in likely demand conditions

Further information on the Cyclohexanol price chart

What is Cyclohexanol

Cyclohexanol is an important industrial chemical with various applications in the production of plastics, chemicals, and solvents. Below is a comprehensive overview covering what cyclohexanol is, its production methods, uses, and key properties.

Cyclohexanol is an organic compound with the chemical formula C₆H₁₁OH. It is a secondary alcohol derived from cyclohexane, featuring a hydroxyl group (–OH) attached to a cyclohexane ring. Cyclohexanol appears as a colorless to pale yellow liquid with a mild, pleasant odor. It is primarily used as an intermediate in the production of other chemicals, most notably adipic acid and caprolactam, which are precursors to nylon.

How is Cyclohexanol produced

Cyclohexanol can be synthesized through several methods, with the most common being the oxidation of cyclohexane and the hydration of cyclohexene. Below are the primary production methods:

Oxidation of Cyclohexane

This is the industrial-scale method for producing cyclohexanol. Reaction Process: Cyclohexane is oxidized in the presence of air or oxygen to produce cyclohexanol and cyclohexanone (a process known as the Koch oxidation). Typically, a cobalt or manganese catalyst is used to facilitate the reaction.

What is Cyclohexanol used for

Cyclohexanol is primarily utilized as an intermediate in the synthesis of various chemicals and materials. Its main applications include:

Production of Adipic Acid and Caprolactam

Adipic Acid: Cyclohexanol is oxidized to produce cyclohexanone, which is further oxidized to adipic acid. Adipic acid is a key precursor in the manufacture of nylon-6,6, used extensively in textiles, automotive parts, and plastics.

Caprolactam: Adipic acid is further processed to produce caprolactam, which is polymerized to form Nylon-6, a vital material in the textile and plastics industries.

Solvent Applications

Cyclohexanol is used as a solvent in various industrial applications due to its ability to dissolve a wide range of substances.

Paints and Coatings: Serves as a solvent in the formulation of paints, varnishes, and coatings.

Resins and Plastics: Used in the production of phenolic resins and other plastic materials.

Chemical Synthesis

Cyclohexanol is a versatile intermediate in the synthesis of numerous chemicals, including:

Cyclohexylamine: Used in the production of rubber chemicals and pharmaceuticals.

Phenol Production: Cyclohexanol can be converted to phenol through dehydrogenation.

Pharmaceuticals and Cosmetics

Cyclohexanol is utilized in the formulation of certain pharmaceuticals and cosmetic products as a solvent and intermediate.

Agrochemicals

Used in the synthesis of pesticides and other agricultural chemicals.

What are the key characteristics of Cyclohexanol

Chemical Properties

Chemical Formula: C₆H₁₁OH

Molecular Weight: 100.16 g/mol

Structure: Cyclohexane ring with a hydroxyl group attached.

Functional Group: Secondary alcohol

Physical Properties

Appearance: Colorless to pale yellow liquid

Odor: Mild, sweet, and aromatic

Melting Point: −25 °C (−13 °F)

Boiling Point: 161 °C (322 °F)

Density: Approximately 0.958 g/cm³ at 25 °C

Solubility: Slightly soluble in water; miscible with most organic solvents like ethanol, ether, and acetone

Vapor Pressure: Relatively low, indicating moderate volatility

Chemical Behavior

Reactivity: Cyclohexanol can undergo typical alcohol reactions, such as oxidation to cyclohexanone, dehydration to cyclohexene, and esterification.

Acidity: As a secondary alcohol, cyclohexanol has moderate acidity, capable of forming cyclohexoxide ions under strong basic conditions.

Stability: Stable under normal conditions but can decompose when exposed to strong oxidizing agents or acids.

How big is the global Cyclohexanol market

Market Size and Growth

Market Valuation (2023): The global cyclohexanol market was valued at approximately USD 700 million in 2023.

Projected Growth: The market is expected to grow at a compound annual growth rate (CAGR) of around 4-6% from 2023 to 2030. By 2030, the market size is anticipated to reach between USD 1.0 to 1.2 billion, depending on various economic and industrial factors.

Key Drivers

Nylon Production:

Adipic Acid and Caprolactam: Cyclohexanol is a primary intermediate in the synthesis of adipic acid and caprolactam, both essential for nylon-6 and nylon-6,6 production. The growing demand for nylon in textiles, automotive components, and consumer goods significantly propels cyclohexanol demand.

Automotive Industry:

Plastics and Polymers: The automotive sector’s increasing use of lightweight plastics and polymers enhances the demand for cyclohexanol-based products.

Solvent Applications:

Paints, Coatings, and Adhesives: Cyclohexanol serves as an effective solvent in various industrial applications, including paints, coatings, and adhesives, contributing to market growth.

Pharmaceuticals and Agrochemicals:

Intermediate for Active Ingredients: Cyclohexanol is utilized in the synthesis of pharmaceuticals and agrochemicals, broadening its application scope.

Technological Advancements:

Process Optimization: Innovations in production processes, such as more efficient catalytic oxidation methods, enhance production capacity and reduce costs, supporting market expansion.

Regional Insights

North America:

Market Share: Holds a significant share due to a well-established chemical industry and high demand from the automotive and textile sectors.

Key Countries: United States and Canada.

Europe:

Sustainability Initiatives: Strong emphasis on sustainable manufacturing practices and stringent environmental regulations influence cyclohexanol production and usage.

Key Countries: Germany, Netherlands, and France.

Asia-Pacific:

Highest Growth Rate: Expected to witness the fastest growth, driven by rapid industrialization, expanding automotive and textile industries, and increasing investments in chemical manufacturing.

Key Countries: China, India, Japan, and South Korea.

Latin America and Middle East & Africa:

Emerging Markets: Growing industrial activities and infrastructural developments contribute to the rising demand for cyclohexanol.

Key Countries: Brazil, Saudi Arabia, and South Africa.

Major Players and Competitive Landscape

The global cyclohexanol market is moderately fragmented, with key players focusing on strategic expansions, partnerships, and technological innovations to enhance their market presence. Major companies include:

Honeywell International Inc.

BASF SE

Huntsman Corporation

Perstorp Group

Eastman Chemical Company

Ascend Performance Materials

Clariant AG

LyondellBasell Industries

INEOS Group

Dow Chemical Company

Challenges and Restraints

Environmental Regulations:

Emission Controls: Strict regulations on emissions and waste management in chemical production can increase operational costs and impact profitability.

Raw Material Price Volatility:

Feedstock Costs: Fluctuations in the prices of raw materials, such as cyclohexane and other petrochemicals, can affect production costs and market pricing.

Competition from Alternatives:

Substitute Chemicals: Availability of alternative solvents and intermediates may limit cyclohexanol market growth in certain applications.

Opportunities

Green Chemistry:

Sustainable Production Methods: Adoption of environmentally friendly production processes can open new market opportunities and comply with regulatory standards.

Expansion in Emerging Markets:

Infrastructure Development: Growing industrial infrastructure in emerging economies presents significant growth prospects for cyclohexanol manufacturers.

Innovation in Applications:

New Uses: Exploration of cyclohexanol in novel applications, such as advanced materials and specialty chemicals, can drive demand.

Conclusion

The global cyclohexanol market is poised for steady growth over the next decade, underpinned by its essential role in producing nylon precursors, solvents, and various industrial chemicals. While challenges such as environmental regulations and raw material price volatility exist, opportunities in sustainable production and expanding industrial sectors, particularly in the Asia-Pacific region, are expected to drive market expansion. Major industry players continue to invest in technological advancements and strategic initiatives to capitalize on emerging opportunities and strengthen their market positions.