Grain oriented electrical steel price February 2025 and outlook (see chart below)

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Grain oriented electrical steel price index

This post is a summary of the Grain oriented electrical steel price developments. The price developments of Grain oriented electrical steel are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Grain oriented electrical steel price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for electrical steel prices is generated from different inputs including:

- Very recent price developments of immediate cost drivers of electrical steel prices

- Recent price developments of underlying feedstocks which drive the price of Grain oriented electrical steel

- Market futures for both cost drives and feedstocks of Grain oriented electrical steel prices

- Adjustment of current supply/demand imbalances in the electrical steel market

- Longer term trends in likely demand conditions

Further information on Grain oriented electrical steel price index

Here is some further information

What is grain-oriented electrical steel

Grain-oriented electrical steel (GOES) is a specialized type of electrical steel used in the construction of transformers, motors, generators, and other electrical devices. It is designed to have specific magnetic properties that make it highly efficient in converting electrical energy to magnetic energy and vice versa.

The unique characteristic of grain-oriented electrical steel lies in its grain structure. The grains within the steel are oriented in a particular direction to optimize its magnetic properties. This orientation of grains minimizes the magnetic losses that can occur when the steel is subjected to alternating magnetic fields, such as those found in transformers and other electrical equipment.

The manufacturing process for grain-oriented electrical steel involves carefully controlling the crystalline structure of the material. This is achieved through a combination of hot rolling and controlled cooling processes. The resulting steel sheet has a distinctive grain pattern that aligns with the desired magnetic flux direction.

Key properties of grain-oriented electrical steel include:

High magnetic permeability

This property allows the material to conduct magnetic flux effectively, reducing energy losses and improving the efficiency of electrical devices.

Low core loss

Grain-oriented electrical steel exhibits low hysteresis and eddy current losses, which are critical factors in maintaining the efficiency of transformers and other electromagnetic devices.

Directional magnetic properties

The grains are aligned in the rolling direction, which provides superior performance in applications where the magnetic flux is predominantly in one direction.

Anisotropic behavior

The magnetic properties of grain-oriented electrical steel are different along different crystallographic directions, making it suitable for specific applications.

Grain-oriented electrical steel is typically produced in thin sheets or strips, which are then used to construct the cores of transformers, rotating machinery, and other electrical equipment where minimizing energy losses and maximizing efficiency are essential considerations.

In its crystalline form, silica is used to make glass, ceramics, and abrasives. In its amorphous form, it is used as a filler in rubber, plastics, and paint, and it is also used as an absorbent in the food and pharmaceutical industries.

Overall, silica plays a vital role in many different industries and is an important component of many products that we use every day.

What is GOES used for?

Grain-oriented electrical steel (GOES) is primarily used in the construction of electrical devices and equipment where efficient energy conversion between electrical and magnetic fields is crucial. Here are some of the main applications of GOES:

Transformers: GOES is extensively used in the cores of power transformers. Transformers are vital components of electrical distribution systems that step up or step down voltage levels for efficient transmission and distribution of electricity. The low core loss and high magnetic permeability of GOES help minimize energy losses and improve the overall efficiency of transformers.

Generators: GOES is used in the construction of generators, both in traditional power plants and in renewable energy systems such as wind turbines. Generators convert mechanical energy into electrical energy through the interaction of magnetic fields, and GOES cores contribute to reducing energy losses during this process.

Motors: Electric motors, whether used in industrial machinery, appliances, or automobiles, require efficient conversion of electrical energy into mechanical energy. GOES cores in motor constructions help optimize the magnetic flux paths, reducing losses and enhancing motor efficiency.

Inductors and Chokes: Inductors and chokes are passive electronic components that store and control magnetic energy. GOES is used in their construction to minimize energy losses and improve their overall performance.

Reactors: Reactors are devices used to control current in electrical circuits. They are employed in various applications, including power factor correction and harmonic filtering. GOES cores in reactors help control and manage magnetic flux, reducing energy losses.

Magnetic Amplifiers: Magnetic amplifiers are devices used to control the flow of current in electrical circuits by varying the magnetic flux. GOES cores are utilized in their construction to enhance their efficiency and performance.

Instrument Transformers: Instrument transformers, such as current transformers and voltage transformers, are used in metering and protection applications within power systems. GOES cores help maintain accurate measurements and proper functioning of these devices.

Electric Vehicle Components: As electric vehicles (EVs) become more common, GOES is finding applications in the construction of components like motors and charging systems, where energy efficiency is a critical concern.

The unique magnetic properties of GOES make it an essential material in applications where minimizing energy losses and improving the overall efficiency of electrical devices is of paramount importance. Its use contributes to the optimization of various electrical systems, which in turn helps conserve energy and reduce environmental impact.

How is grain-oriented electrical steel produced

The production of grain-oriented electrical steel (GOES) involves several specialized manufacturing processes to achieve the desired magnetic properties and grain orientation. The process is carefully controlled to ensure the material’s high efficiency in converting electrical energy to magnetic energy and vice versa. Here’s an overview of the production process for GOES:

Raw Material Preparation

The production of GOES begins with high-quality raw materials, primarily iron and silicon. These materials are mixed and melted in an electric arc furnace to create molten steel.

Casting

The molten steel is then cast into thin slabs through continuous casting. Continuous casting involves pouring the molten steel into water-cooled molds to form solid slabs. These slabs are typically around 8 to 10 mm thick.

Hot Rolling

The slabs are reheated and passed through a series of hot rolling mills. During hot rolling, the slabs are progressively reduced in thickness while being elongated in length. This process helps align the crystal structure and refine the grain orientation in the material.

Annealing

After hot rolling, the steel is subjected to annealing, a heat treatment process. Annealing involves heating the steel to a specific temperature and then slowly cooling it to relieve internal stresses, soften the material, and further optimize its grain orientation. This step is critical for achieving the desired magnetic properties of GOES.

Cold Rolling

The annealed steel is then cold rolled to further reduce its thickness and improve its surface finish. Cold rolling also helps refine the grain structure and enhance the material’s magnetic properties.

Final Annealing

Another annealing step follows cold rolling. This final annealing process is designed to achieve the desired magnetic properties, including high magnetic permeability and low core loss. The material is heated and carefully cooled in controlled atmospheres to achieve the desired grain orientation.

Insulating Coating

To reduce eddy current losses in the final product, a thin insulating coating is applied to the surface of the GOES sheets. This coating prevents the formation of circulating currents within the steel when it’s exposed to alternating magnetic fields.

Shearing and Slitting

The coated GOES sheets are cut into specific sizes and shapes according to the requirements of various applications. This may involve shearing and slitting processes.

Quality Control and Testing

Throughout the production process, quality control measures are implemented to ensure that the material meets the required specifications for magnetic properties, thickness, and surface finish. Various tests are conducted to verify the performance of the GOES.

The complex combination of controlled heating, cooling, and rolling processes, as well as the specific annealing treatments, are key to producing grain-oriented electrical steel with its unique magnetic properties and directional grain structure. The precision and care in each step of the production process contribute to the high efficiency and performance of GOES in various electrical applications.

What drives the cost of grain oriented electrical steel

The cost of grain-oriented electrical steel (GOES) is influenced by a variety of factors, including raw materials, manufacturing processes, market demand, and technological advancements. Here are some of the key factors that drive the cost of GOES:

Raw Material Costs

The primary raw materials used in GOES production are iron and silicon. Fluctuations in the prices of these raw materials can significantly impact the overall cost of producing GOES. Supply and demand dynamics, geopolitical factors, and changes in production capacities can all influence raw material costs.

Manufacturing Processes

The production of GOES involves a series of specialized and energy-intensive manufacturing processes, including melting, casting, rolling, annealing, and coating. Each step requires specific equipment, energy inputs, and skilled labor. Any improvements or changes in these processes can affect production costs.

Energy Costs

The manufacturing of GOES requires substantial energy inputs, particularly in the heating and annealing stages. Changes in energy prices can have a direct impact on the overall cost of production.

Technological Advances

Advances in manufacturing technology and process optimization can lead to cost reductions. Improved efficiency, automation, and innovative production techniques can streamline processes and lower production costs over time.

Scale of Production

Economies of scale play a role in the cost of GOES production. Higher production volumes can help spread fixed costs across more units, reducing the cost per unit produced.

Market Demand and Supply

Supply and demand imbalances in the market can influence prices. If demand for GOES exceeds supply, prices may rise, and vice versa.

Regulations and Environmental Factors

Environmental regulations and sustainability initiatives can impact production processes and potentially lead to additional compliance costs.

Currency Exchange Rates

GOES is a globally traded commodity, and currency exchange rates can impact the cost of imported raw materials and equipment, which in turn affects the cost of production.

Labor Costs

Skilled labor is required for various stages of the manufacturing process. Labor costs can vary based on location, labor market conditions, and prevailing wage rates.

Quality and Performance

Higher-quality GOES with superior magnetic properties and minimal defects may command higher prices due to their enhanced performance in electrical applications.

Research and Development

Investments in research and development aimed at improving the magnetic properties and efficiency of GOES can impact costs. However, such investments can also lead to long-term benefits by creating a more competitive and advanced product.

Trade Policies and Tariffs

International trade policies, tariffs, and import/export regulations can influence the cost of GOES in various markets.

Overall, the cost of GOES is a complex interplay of various factors, and it can vary over time due to changes in these factors and market conditions. As technology advances and the demand for efficient electrical devices grows, there may be efforts to develop more cost-effective production methods and materials.

What types of grain-oriented electrical steel are there

There are mainly two types of electrical steel: grain-oriented electrical steel (GOES) and non-grain-oriented electrical steel (NGOES), also known as non-oriented electrical steel. These two types have distinct characteristics and are used in different applications within the electrical and electronics industries.

Grain-Oriented Electrical Steel (GOES)

GOES is characterized by its unique grain structure, where the crystal grains are aligned in a specific direction to optimize magnetic properties. It is primarily used in applications where the magnetic flux predominantly flows in one direction, such as transformers, generators, and certain types of motors. GOES exhibits higher magnetic permeability and lower core loss in the preferred direction, making it highly efficient for applications with alternating magnetic fields.

Non-Grain-Oriented Electrical Steel (NGOES)

NGOES, also known as non-oriented electrical steel, lacks the highly directional grain structure of GOES. It is used in applications where the magnetic flux direction varies, such as motors and generators with rotating magnetic fields, as well as in various components of electrical appliances and machinery. NGOES has lower magnetic permeability and higher core loss compared to GOES but is well-suited for applications requiring isotropic magnetic behavior.

Both GOES and NGOES are essential materials in the electrical and electronics industries, and their properties make them suitable for different types of devices and equipment. The choice between the two types depends on the specific requirements of the application and the direction of the magnetic flux.

GOES market information

The global market for grain-oriented electrical steel (GOES) is valued at around $4.5 billion USD.

According to https://oec.world/ :

Steel, alloy: flat-rolled, width less than 600mm, of silicon-electrical steel, grain-oriented are the world’s 2594th most traded product.

In 2021, the top exporters of Steel, alloy: flat-rolled, width less than 600mm, of silicon-electrical steel, grain-oriented were Malaysia ($79.1M), France ($75.3M), Germany ($72.6M), Japan ($70.4M), and China ($46.2M).

In 2021, the top importers of Steel, alloy: flat-rolled, width less than 600mm, of silicon-electrical steel, grain-oriented were China ($98.9M), United States ($76.2M), Spain ($47.9M), Germany ($33M), and Italy ($30M).

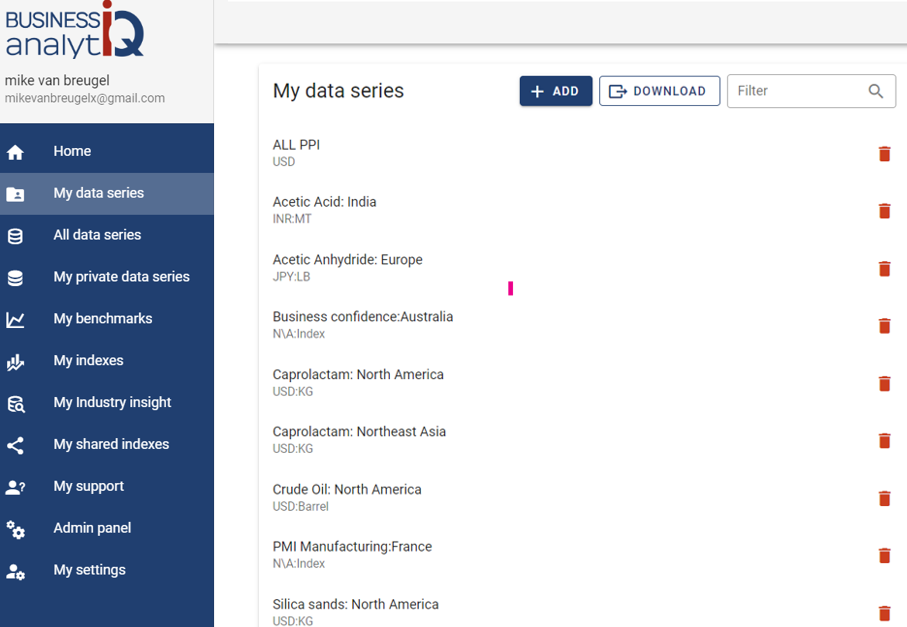

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page