HDPE price February 2025 and outlook (see chart below)

- North America:US$0.93/KG, -1.1% down

- Europe:US$1.38/KG, unchanged

- Africa:US$1.07/KG, -0.9% down

- Northeast Asia:US$1.16/KG, -1.7% down

- Southeast Asia:US$1.13/KG, -0.9% down

- South America:US$1.02/KG, -1.9% down

- Middle East:US$1.03/KG, -1% down

- India:US$1.04/KG, unchanged

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

HDPE price index

This post is a summary of the global HDPE price developments. The price developments of global HDPE prices are expressed in US$ prices converted FX rates applicable at the time when the price was valid. HDPE price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for global HDPE prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of global HDPE resin prices

- Recent price developments of underlying feedstocks which drive the price of HDPE

- Market futures for both cost drives and feedstocks of global HDPE prices

- Adjustment of current supply/demand imbalances in the HDPE market

- Longer term trends in likely demand conditions

Further information on the HDPE price index

What is HDPE

HDPE stands for High-Density Polyethylene, which is a type of polyethylene plastic that is known for its high strength, durability, and resistance to impact and chemicals. HDPE is produced by polymerizing ethylene under high pressure and temperature, resulting in a dense, solid material that is ideal for a wide range of applications.

HDPE is widely used in packaging products, such as plastic bags, bottles, and containers, due to its low cost, light weight, and resistance to moisture and chemical damage. It is also used in construction and infrastructure applications, such as piping and fittings, as well as in the manufacture of products for the automotive, electrical, and consumer goods industries.

HDPE has a number of advantages over other materials, including its high impact resistance, low cost, and ability to withstand extreme temperatures and chemicals. Additionally, HDPE is easily recyclable and has a low carbon footprint, making it an environmentally friendly material for many applications.

How is HDPE produced

HDPE is produced through a process called polymerization, which involves the conversion of ethylene gas into a high-density polyethylene polymer. The process of HDPE production can be summarized as follows:

Preparation of the ethylene feedstock

The ethylene feedstock is prepared by cracking hydrocarbons such as naphtha, natural gas liquids, or gas oil to obtain ethylene.

Polymerization

The ethylene feedstock is polymerized using a catalytic process in which the ethylene molecules are combined to form a long chain polymer. The polymerization reaction is carried out in a reactor at high pressure and temperature.

Purification

The resulting HDPE polymer is purified by removing impurities, such as catalysts and oligomers. The purified HDPE polymer is then cooled and cut into small pellets or granules.

Pelletizing

The purified HDPE polymer is melted and extruded into small pellets or granules, which can be stored and transported to manufacturers for further processing.

The production of HDPE is a complex process that requires specialized equipment and expertise to ensure the quality and consistency of the final product. The exact process may vary slightly depending on the manufacturer and the specific requirements of the application, but the general steps described above are common to most HDPE production processes.

What is HDPE used for

HDPE (High-Density Polyethylene) is a versatile plastic material that is widely used in a variety of applications due to its high strength, durability, and resistance to impact, chemicals, and moisture. Some of the common uses of HDPE include:

Packaging

HDPE is commonly used in packaging products, such as milk jugs, containers, and plastic bags, due to its low cost and resistance to moisture and chemical damage.

Piping

HDPE is widely used in the construction and infrastructure industries for pipes and fittings, due to its high impact resistance, flexibility, and resistance to corrosion.

Consumer goods

HDPE is used in the manufacture of a variety of consumer goods, such as toys, cutting boards, and household appliances, due to its low cost, durability, and ease of processing.

Automotive

HDPE is used in the automotive industry for fuel tanks, battery cases, and other applications that require a durable, lightweight, and resistant material.

Industrial products

HDPE is used in the manufacture of a variety of industrial products, such as drums, pallets, and storage containers, due to its strength, durability, and resistance to impact and chemicals.

HDPE is also widely used in many other applications due to its excellent properties and low cost, making it a popular choice for manufacturers and consumers alike.

What are specific properties of HDPE

HDPE (High-Density Polyethylene) is a type of polyethylene plastic that is known for its unique combination of properties, which make it a popular choice for a wide range of applications. Some of the specific properties of HDPE include:

High strength

HDPE has a high strength-to-density ratio, making it ideal for applications that require a strong and durable material.

Chemical resistance

HDPE is resistant to a wide range of chemicals, including acids, bases, and solvents, making it ideal for use in environments where exposure to chemicals is a concern.

Impact resistance

HDPE has a high impact resistance, making it ideal for applications that may be subjected to sudden impacts, such as pipes and fittings for the construction and infrastructure industries.

Moisture resistance

HDPE is resistant to moisture, making it ideal for use in applications where exposure to water is a concern, such as packaging products and piping.

Low temperature resistance

HDPE is flexible at low temperatures and does not become brittle, making it ideal for use in cold environments.

Food-grade quality

HDPE is safe for use in food-contact applications, making it ideal for use in food packaging and storage containers.

Ease of processing

HDPE is easy to process and can be easily molded into a wide range of shapes and sizes, making it ideal for use in many applications.

Recyclability

HDPE is a highly recyclable material, making it an environmentally friendly choice for many applications.

These properties, combined with its low cost and versatility, make HDPE a popular choice for manufacturers and consumers alike in a wide range of applications.

What drives the cost of HDPE

The cost of HDPE (High-Density Polyethylene) is driven by a number of factors, including:

Raw material costs

The cost of the raw materials used to produce HDPE, including ethylene and catalysts will greatly impact the cost of HDPE.

Energy costs

The energy required to produce HDPE, including the production of ethylene and the processing of HDPE

Production capacity

The availability of production capacity for HDPE can also impact its cost.

Transportation costs

The cost of transportation can also impact the cost of HDPE, as it is often shipped over long distances from production facilities to consumers.

Government regulations

Government regulations and taxes on the production and use of HDPE can also impact its cost.

Currency exchange rates

The exchange rate between the currency used to produce HDPE and the currency used by its buyers can also impact the cost of HDPE.

These are some of the major factors that can drive the cost of HDPE

What types of HDPE are there

There are several types of HDPE (High-Density Polyethylene) that are differentiated based on their properties, including:

Virgin HDPE

This is pure HDPE that has not been recycled or reprocessed. It is characterized by its high strength and clarity, making it ideal for applications where these properties are important.

Reprocessed HDPE

This is HDPE that has been recycled and reprocessed. It is characterized by its lower strength and clarity compared to virgin HDPE, but it is still a cost-effective alternative for many applications.

Blended HDPE

This is a mixture of virgin HDPE and reprocessed HDPE. The properties of blended HDPE are intermediate between those of virgin HDPE and reprocessed HDPE.

Anti-block HDPE

This is HDPE that has been formulated to have low surface friction, making it ideal for use in applications where blocks or clumps of material need to be prevented, such as in the manufacture of plastic bags.

UV-stabilized HDPE

This is HDPE that has been formulated to resist degradation from ultraviolet (UV) light exposure, making it ideal for outdoor applications such as pipes and outdoor furniture.

Flame-retardant HDPE

This is HDPE that has been formulated to be self-extinguishing in the event of a fire, making it ideal for use in applications where fire safety is a concern.

These are some of the most common types of HDPE, and they are used in a wide range of applications due to their unique properties. The type of HDPE used in a specific application will depend on the specific requirements of that application, including the desired properties, processing conditions, and cost considerations.

Which countries produce the most HDPE

The production of HDPE (High-Density Polyethylene) is a global industry, with significant production taking place in many countries around the world. Some of the largest producers of HDPE include:

China

China is one of the largest producers of HDPE globally and has a significant share of the world market.

United States

The United States is also a significant producer of HDPE, with a large number of production facilities located across the country.

Saudi Arabia

Saudi Arabia is a major producer of HDPE, with several large-scale production facilities located in the country.

Russia

Russia is also a significant producer of HDPE, with a number of production facilities located across the country.

Iran

Iran is another major producer of HDPE, with a number of large-scale production facilities located in the country.

These are some of the largest producers of HDPE globally, but there are also significant producers located in many other countries, including Europe, Southeast Asia, and South America.

The exact distribution of production across countries can vary depending on a number of factors, including the availability of raw materials, production costs, and market demand.

How big is the global HDPE market

The global HDPE (High-Density Polyethylene) market is a large and growing industry, with demand for HDPE continuing to rise in many applications. As of 2021, the global HDPE market size was estimated to be worth over $80 billion and is expected to continue growing at a healthy pace in the coming years, driven by increasing demand from a variety of end-use industries.

Factors contributing to the growth of the HDPE market include its low cost, good chemical resistance, and versatility in a wide range of applications, including packaging, construction, agriculture, and others. Additionally, advances in HDPE production technology and the development of new grades of HDPE with improved properties are also driving the growth of the market.

It is difficult to estimate the exact size of the global HDPE market, as it can vary depending on a number of factors, including the state of the global economy, the prices of raw materials, and the level of demand from different end-use industries. However, it is widely expected to continue growing in the coming years, driven by the increasing demand for HDPE in a wide range of applications.

According to https://oec.world/ :

Polyethylene are the world’s 53rd most traded product.

In 2018, the top exporters of Polyethylene were Saudi Arabia ($10.7B), United States ($5.97B), Belgium ($4.21B), Germany ($3.1B), and Singapore ($3.06B).

In 2018, the top importers of Polyethylene were China ($10.5B), Germany ($2.99B), United States ($2.61B), Singapore ($2.22B), and Italy ($2.06B).

Further information

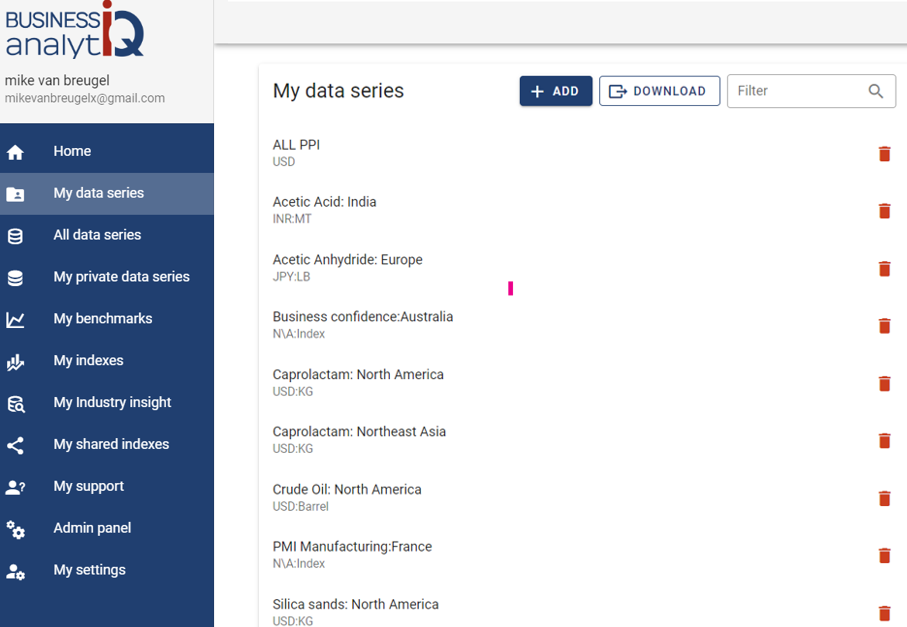

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page