Isophorone diisocyanate (IPDI) price February 2025 and outlook (see chart below)

- Northeast Asia:US$4.2/KG, -2.6% down

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, fitness for purpose or timeliness.

Isophorone diisocyanate (IPDI) price index

This post is a summary of the Isophorone diisocyanate (IPDI) price developments. The price developments of Isophorone diisocyanate (IPDI) are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Isophorone diisocyanate (IPDI) price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Isophorone diisocyanate (IPDI) prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of Isophorone diisocyanate (IPDI) prices

- Recent price developments of underlying feedstocks which drive the price of Isophorone diisocyanate (IPDI)

- Market futures for both cost drives and feedstocks of Isophorone diisocyanate (IPDI) prices

- Adjustment of current supply/demand imbalances in the Isophorone diisocyanate (IPDI) market

- Longer term trends in likely demand conditions

Further information on the Isophorone diisocyanate (IPDI) price index

Here is some further information

What is IPDI

IPDI, or isophorone diisocyanate, is a chemical compound that is used in the production of polyurethane resins, plastics, and other products. It is a colorless liquid with a strong, unpleasant odor that is highly reactive and can be harmful if inhaled or ingested.

IPDI is produced by the reaction of isocyanic acid with isophorone, a chemical compound that is derived from petroleum. It is used as a building block for the production of polyurethane resins and other polymers.

IPDI is used in a wide range of applications, including the production of coatings, adhesives, sealants, and foams. It is also used in the production of fibers, films, and elastomers.

IPDI is a hazardous chemical and should be handled with caution. Protective measures should be taken when working with IPDI to avoid exposure to it.

How is IPDI produced

IPDI (isophorone diisocyanate) is a chemical compound that is used as a raw material in the production of polyurethane polymers. It is typically produced through a chemical reaction between isophorone and an excess of an aromatic diisocyanate, such as toluene diisocyanate (TDI) or methylene diphenyl diisocyanate (MDI).

The production of IPDI typically involves the following steps:

Preparation of reactants

The isophorone and the aromatic diisocyanate are weighed and prepared according to the desired stoichiometric ratio.

Mixing

The reactants are mixed together, typically using a mechanical stirrer or a high-shear mixer.

Reaction

The mixture is heated to a temperature of around 140-180°C to initiate the chemical reaction between the isophorone and the diisocyanate. The reaction is exothermic, meaning that it releases heat as it progresses.

Distillation

The reaction mixture is distilled to separate the IPDI from any by-products or unreacted reactants.

Purification

The IPDI is purified through a series of steps, including filtration and distillation, to remove impurities and produce a high-quality product.

It is important to note that the production of IPDI, like any chemical process, requires careful handling and strict adherence to safety protocols to ensure the safety of workers and the environment.

What drives the cost of IPDI

The cost of isophorone diisocyanate (IPDI) is driven by several factors, including:

Raw Materials

The cost of the raw materials used to produce IPDI, such as aniline and formaldehyde, can significantly impact the overall cost of the product. Fluctuations in the prices of these raw materials can result in changes in the price of IPDI.

Energy Costs

Energy costs, such as the cost of electricity and natural gas, are significant factors in the production of IPDI. Changes in energy prices can result in corresponding changes in the cost of IPDI.

Production Capacity

The availability of production capacity and the level of competition in the market can also impact the cost of IPDI.

Transportation Costs

The cost of transportation can also impact the price of IPDI, as the product is often transported over long distances from the production site to the customer. Changes in transportation costs, such as changes in fuel prices or the cost of shipping, can result in corresponding changes in the price of IPDI.

Regulations

Government regulations, such as environmental regulations and taxes, can also impact the cost of IPDI. These regulations can increase the cost of production, which is reflected in the price of the final product.

In summary, the cost of IPDI is influenced by a complex interplay of factors, including the availability of raw materials, energy costs, production capacity, transportation costs, and government regulations.

What is IPDI used for

IPDI (isophorone diisocyanate) is a chemical compound that is used as a raw material in the production of polyurethane polymers. Polyurethanes are a class of polymers that are formed through the reaction of a polyol with a diisocyanate, such as IPDI. The properties of the resulting polymer can be modified by changing the type and amount of polyol and diisocyanate used, as well as by adding other chemicals called chain extenders and crosslinkers.

Polyurethanes are used in a wide range of applications, including:

Coatings

Polyurethane coatings are used to protect surfaces from wear, corrosion, and other types of damage. They are often used on metal surfaces, such as automotive parts and aircraft components, as well as on wood and other materials.

Adhesives

Polyurethane adhesives are used to bond together a variety of materials, including metal, plastic, and wood. They are known for their strong bond strength and ability to withstand temperature changes and other harsh conditions.

Insulation

Polyurethane foam is used as an insulation material in buildings, appliances, and other applications to reduce heat loss and improve energy efficiency.

Foams

Polyurethane foam is used in a wide range of products, including upholstery, bedding, and cushions, for its cushioning and comfort properties. It is also used in the construction of vehicles and boats, as well as in packaging and insulation applications.

Elastomers

Polyurethane elastomers are highly flexible and stretchy materials that are used in a variety of applications, including tires, seals, and gaskets.

Cast resins

Polyurethane cast resins are used in the production of prototypes and other low-volume parts. They are known for their accuracy, surface finish, and ability to produce complex shapes.

Overall, IPDI and polyurethanes made from it are widely used in a variety of applications due to their versatility, durability, and performance characteristics.

How big is the global IPDI market

The global market for isophorone diisocyanate (IPDI) is growing due to increasing demand from various end-use industries, such as automotive, construction, and packaging. The market size of IPDI is influenced by factors such as production capacity, demand for polyurethane products, and economic conditions.

The global IPDI market was valued at approximately USD 1.4 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. The growth of the market is driven by the increasing demand for polyurethane products in various end-use industries, such as construction, automotive, and packaging.

Which countries produce the most IPDI

IPDI is produced globally by several countries, with some of the major producers being:

China

China is a major producer of IPDI, with several large-scale production facilities located in the country. China’s growing demand for polyurethane products has driven the growth of the IPDI industry in the country.

Europe

Europe is also a significant producer of IPDI, with several major chemical companies operating production facilities in the region. The demand for IPDI in Europe is driven by the region’s strong polyurethane industry.

North America

North America is also a significant producer of IPDI, with several major chemical companies operating production facilities in the region. The demand for IPDI in North America is driven by the region’s strong automotive and construction industries.

Japan

Japan is a significant producer of IPDI, with several large-scale production facilities located in the country. The demand for IPDI in Japan is driven by the country’s strong electronics and automotive industries.

Which are some of the companies which produce IPDI

There are several large companies that produce isophorone diisocyanate (IPDI), including:

BASF

BASF SE is one of the largest producers of IPDI, with production facilities located globally. The company is a leading supplier of polyurethane raw materials and is committed to expanding its IPDI production capacity to meet the growing demand for polyurethane products.

Covestro

Covestro AG is a leading producer of IPDI, with production facilities located globally. The company is focused on innovation and sustainability in the polyurethane industry and is committed to expanding its IPDI production capacity to meet the growing demand for polyurethane products.

Huntsman

Huntsman Corporation is a leading producer of IPDI, with production facilities located globally. The company is focused on innovation and sustainability in the polyurethane industry and is committed to expanding its IPDI production capacity to meet the growing demand for polyurethane products.

Tosoh Corporation

Tosoh Corporation is a leading producer of IPDI, with production facilities located in Japan and Asia. The company is focused on innovation and sustainability in the polyurethane industry and is committed to expanding its IPDI production capacity to meet the growing demand for polyurethane products.

In conclusion, BASF SE, Covestro AG, Huntsman Corporation, and Tosoh Corporation are some of the largest producers of IPDI globally. These companies are committed to expanding their production capacity to meet the growing demand for polyurethane products and are focused on innovation and sustainability in the polyurethane industry.

Further reading

- Wikipedia for general, history, production and usage information

- PubChem for chemistry and property information

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

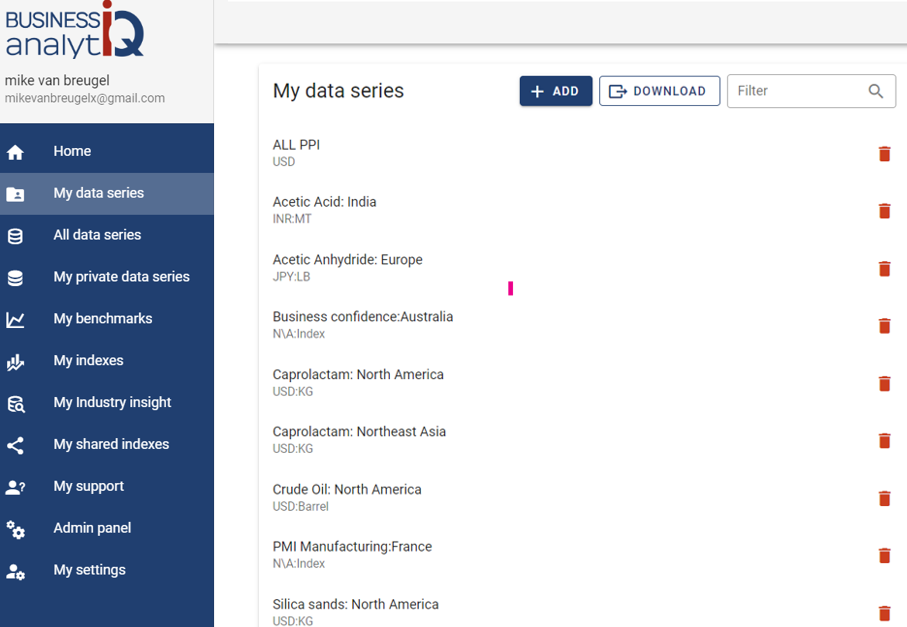

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.