Melamine resin price April 2024 and outlook (see chart below)

- North America:US$1.29/KG, 1.6% up

- Europe:US$1.13/KG, -6.6% down

- Northeast Asia:US$1.96/KG, -3% down

- South America:US$2.52/KG, 1.6% up

Melamine resin price index

This post is a summary of the global Melamine resin price developments. The price developments of global Melamine resin are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Melamine resin price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for global Melamine resin prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of global Melamine resin prices

- Recent price developments of underlying feedstocks which drive the price of Melamine resin

- Market futures for both cost drives and feedstocks of global Melamine resin prices

- Adjustment of current supply/demand imbalances in the Melamine resin market

- Longer term trends in likely demand conditions

Further information on the Melamine resin price chart

What is Melamine resin

Melamine resin, also known as melamine formaldehyde resin, is a type of thermosetting plastic made by combining melamine and formaldehyde. It is widely used in various applications due to its desirable properties, including its durability, heat resistance, chemical resistance, and ability to form a smooth, hard surface.

Key characteristics and uses of melamine resin

Chemical Composition

Melamine resin is produced through a chemical reaction between melamine (a white crystalline compound) and formaldehyde (a colorless gas). This reaction creates a cross-linked polymer with a three-dimensional network structure.

Properties

Heat Resistance

Melamine resin exhibits excellent heat resistance, making it suitable for applications where exposure to high temperatures is a concern. It can withstand temperatures up to around 150-180°C (300-356°F) without deforming or degrading.

Durability

It is highly durable and resistant to wear, impact, and scratching, which makes it ideal for tabletops, countertops, and other surfaces subjected to daily use.

Chemical Resistance

Melamine resin is resistant to many chemicals, including acids and bases, which contributes to its longevity and suitability for laboratory equipment and chemical-resistant coatings.

Smooth Finish

It can be molded to create a smooth, hard surface that is easy to clean and maintain.

Electrical Insulation

Melamine resin is an excellent electrical insulator, and it is used in electrical components and insulating materials.

What is Melamine resin used for

Dinnerware and Tableware

Melamine resin is commonly used in the production of melamine dinnerware, including plates, bowls, and cups. It is appreciated for its lightweight nature, durability, and resistance to breakage.

Kitchen Countertops

Due to its heat resistance and durability, melamine resin is used as a surface material for kitchen countertops and cabinetry.

Furniture

It is used in the manufacturing of furniture, especially laminated particleboard and medium-density fiberboard (MDF) used in shelving and cabinets.

Coatings

Melamine resin is used as a coating material for wood and paper products to enhance their surface durability and appearance.

Lab Equipment

It is used in the production of laboratory countertops and cabinets due to its chemical resistance.

Electrical Insulators

Melamine resin is used in electrical components, such as connectors and insulating materials, because of its electrical insulating properties.

It’s important to note that while melamine resin has many beneficial properties, it should not be confused with pure melamine (melamine powder), which is a raw material used in the production of melamine resin but does not possess the same level of durability and heat resistance.

How is melamine produced

Melamine resin is produced through a chemical process that involves the reaction between melamine and formaldehyde. This reaction creates a cross-linked polymer with a three-dimensional network structure. Here are the basic steps involved in the production of melamine resin:

Melamine Production

The process typically begins with the production of melamine, which is synthesized from urea. Urea is subjected to high temperatures and pressures in the presence of catalysts to form melamine crystals. These melamine crystals are then harvested and used as the primary raw material for melamine resin production.

Formaldehyde Production

Formaldehyde is produced separately through the oxidation of methanol. This involves subjecting methanol to oxidation using air or oxygen in the presence of a catalyst. The resulting formaldehyde gas is then condensed and collected.

Resin Formation

To create melamine resin, melamine and formaldehyde are combined in the desired ratio in a reactor vessel. The mixture is often heated to initiate the chemical reaction. An acid or base catalyst is typically added to facilitate the reaction. The reaction between melamine and formaldehyde involves the formation of methylene bridges (-CH2-) between the melamine molecules, leading to the creation of a three-dimensional network structure.

Heat and Pressure

Once the reaction has begun, heat and pressure are applied to promote the formation of cross-links between the melamine and formaldehyde molecules. This process is called “curing” or “polycondensation.” The specific conditions, such as temperature and pressure, can vary depending on the desired properties of the melamine resin.

Cooling and Solidification

After the desired level of polymerization has been achieved, the melamine resin mixture is cooled and allowed to solidify. The result is a solid, thermosetting plastic with a hard, durable, and heat-resistant structure.

Quality Control

Quality control measures are implemented to ensure that the melamine resin meets the required specifications and standards. This may involve testing the resin for properties such as heat resistance, hardness, chemical resistance, and curing completeness.

Storage and Packaging

The final melamine resin product is typically stored in suitable containers and may be further processed or used as a raw material in various industries.

It’s important to note that the specific formulation and production conditions can vary depending on the intended application of the melamine resin and the manufacturer’s requirements. Additionally, environmental and safety considerations are important in the production of melamine resin, as formaldehyde is a volatile and potentially hazardous substance, and proper handling and waste management are essential

.

What drives the cost of Melamine

The cost of melamine resin is influenced by several factors, and understanding these factors can help explain why the price of melamine resin can vary. Some of the key drivers of the cost of melamine resin include:

Raw Material Costs

The primary raw materials for melamine resin production are melamine and formaldehyde. The prices of these raw materials can fluctuate based on factors such as supply and demand, production costs, and market conditions. Any significant changes in the cost of melamine and formaldehyde will directly impact the overall cost of melamine resin.

Production Scale

Economies of scale play a significant role in the cost of production. Larger manufacturing facilities can produce melamine resin in larger quantities, which can lead to lower production costs per unit. Smaller or less efficient facilities may have higher production costs, affecting the final product’s price.

Energy Costs

The production of melamine resin requires energy for heating, cooling, and other processes. Fluctuations in energy prices can impact production costs and, subsequently, the cost of melamine resin.

Labor Costs

Labor costs, including wages and benefits for workers involved in the production process, can influence the overall cost of melamine resin. Labor costs may vary depending on the location of the manufacturing facility and labor market conditions.

Transportation and Logistics

The cost of transporting raw materials to the manufacturing facility and shipping the finished melamine resin products to customers can contribute to the overall cost. Transportation costs can vary depending on factors like distance, mode of transport, and fuel prices.

Quality and Additives

The use of additives or quality-enhancing measures can impact the cost. High-quality melamine resins may require additional processing steps or the use of specific additives to meet certain performance standards, which can affect costs.

Regulatory Compliance

Compliance with environmental and safety regulations can add costs to the production process. Manufacturers may need to invest in pollution control equipment, safety measures, and waste management, which can influence the final product’s cost.

Market Conditions

Market forces, including supply and demand dynamics, can influence the pricing of melamine resin. Changes in market conditions, such as increased demand or competition, can lead to price fluctuations.

Research and Development

Investment in research and development to improve the properties of melamine resin or develop new applications can contribute to costs. However, such investments can also result in higher-quality products that command premium prices.

Exchange Rates

For manufacturers that rely on imported raw materials or export their products, fluctuations in exchange rates can affect costs. Exchange rate movements can impact the cost of imported raw materials or the competitiveness of exported products.

Customization and Specialized Formulations:

If customers require customized formulations or specialized properties in melamine resin products, additional research and development efforts may be necessary, potentially increasing production costs.

Overall, the cost of melamine resin is influenced by a complex interplay of these factors, and it can vary over time and from one manufacturer to another. Manufacturers carefully manage these factors to optimize production efficiency and maintain competitiveness in the market

What types of melamine resin are there

Melamine resin can be categorized into different types based on variations in its chemical composition, properties, and intended applications. Here are some common types of melamine resin:

Melamine-Formaldehyde (MF) Resin

This is the most common type of melamine resin.

It is produced by the reaction between melamine and formaldehyde. MF resins are known for their excellent heat resistance and durability. They are widely used in the production of laminated countertops, dinnerware, particleboard, and furniture coatings.

Melamine-Urea-Formaldehyde (MUF) Resin

MUF resins are produced by combining melamine, urea, and formaldehyde. They offer a balance between cost-effectiveness and improved performance compared to MF resins. MUF resins are commonly used in particleboard and plywood manufacturing, especially for interior applications.

Melamine-Phenolic Resin (MP Resin)

MP resins are a combination of melamine and phenolic resins.

They exhibit enhanced resistance to moisture and chemical exposure. MP resins are often used in applications where extreme durability and resistance to harsh environments are required, such as in laboratory countertops and chemical-resistant coatings.

Melamine-Modified Resins

These resins involve modifications to the melamine resin formula to achieve specific properties. For example, melamine-cyanurate resins are used as flame retardants in various products due to their ability to inhibit the spread of flames.

Cross-Linked Melamine Resins

Some melamine resins are engineered to have a higher degree of cross-linking, resulting in even greater heat resistance and durability. Cross-linked melamine resins are often used in demanding applications, such as electrical components and high-temperature coatings.

Low-Formaldehyde Melamine Resins

As environmental regulations have become stricter, low-formaldehyde or formaldehyde-free melamine resins have been developed. These resins are designed to reduce or eliminate formaldehyde emissions, making them suitable for eco-friendly and indoor air quality-sensitive applications, such as furniture and cabinetry for residential use.

Thermosetting vs. Thermoplastic Melamine Resins

Most melamine resins are thermosetting, which means they harden irreversibly when exposed to heat. In contrast, thermoplastic melamine resins are designed to soften and melt when heated, allowing for reprocessing and reshaping. Thermoplastic variants are less common and typically used in specialized applications.

Specialized Melamine Resins

Depending on the intended use, specialized melamine resins may be formulated with additives or modifiers to achieve specific properties, such as improved adhesion, UV resistance, or fire resistance. The choice of melamine resin type depends on the application’s requirements, such as the desired level of heat resistance, durability, moisture resistance, and cost considerations. Manufacturers often tailor the resin formulation to meet the specific needs of their products and industries

How big is the melamine resin market

According to https://oec.world/ :

Melamine are the world’s 2376th most traded product.

In 2020, the top exporters of Melamine were China ($227M), Netherlands ($93.4M), Germany ($92.2M), Poland ($38M), and Austria ($33M).

In 2020, the top importers of Melamine were Turkey ($54.8M), India ($37.5M), Italy ($36.7M), United Kingdom ($30M), and Brazil ($28.6M).

Further information

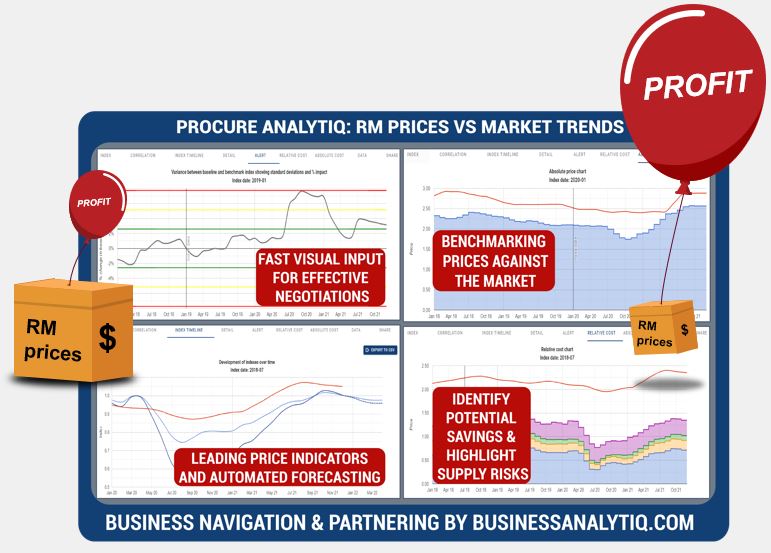

Business Analytiq

BE THE FIRST TO SEE RISK AND OPPORTUNITY!

BusinessAnalytiq provides unlimited market trend data and an online tools to track market developments, key benchmarks & leading indicators.

BusinessAnalytiq leads to price visibility, better negotiations, easier budgeting and forecasting, lower raw material prices, and improved better internal and external communication. BusinessAnalytiq will decrease risk and higher profit.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page