Methylene diphenyl diisocyanate (Pure) price April 2024 and outlook (see chart below)

- North America:US$2.16/KG, 1.4% up

- Europe:US$2.21/KG, 2.8% up

- Northeast Asia:US$1.93/KG, -2% down

- Middle East:US$1.61/KG, -1.2% down

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Methylene diphenyl diisocyanate (MDI) price index

This post is a summary of the global Methylene diphenyl diisocyanate (MDI) price developments. The price developments of Methylene diphenyl diisocyanate (MDI) are expressed in US$ prices converted FX rates applicable at the time when the price was valid. MDI price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for Methylene diphenyl diisocyanate (MDI) prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of global MDI prices

- Recent price developments of underlying feedstocks which drive the price of Methylene diphenyl diisocyanate (MDI)

- Market futures for both cost drives and feedstocks of global Methylene diphenyl diisocyanate (MDI) prices

- Adjustment of current supply/demand imbalances in the Methylene diphenyl diisocyanate (MDI) market

- Longer term trends in likely demand conditions

Further information on the Methylene diphenyl diisocyanate (MDI) price chart

What is MDI

MDI stands for Methylene Diphenyl Diisocyanate. It is an organic compound that belongs to the class of isocyanates. It is a colorless, flammable liquid that is used as a raw material in the production of polyurethane (PU) materials.

When MDI is reacted with a polyalcohol, such as polyethylene glycol, it forms a polyurethane polymer. The polyurethane polymer can be further processed to form a wide range of products, including rigid foams for insulation and structural applications, flexible foams for seating and bedding, coatings, adhesives, and sealants.

MDI is also used in the production of polyurea, which is a type of polymer that can be used for coatings, linings, and sealants.

MDI is widely used in the construction, automotive, furniture, electronics, and packaging industries. Due to its unique properties and versatility, it has many applications, such as insulation for buildings, car seats, and appliances, as well as in adhesives, sealants, and coatings.

What is MDI used for

MDI is primarily used as a raw material in the production of polyurethane (PU) materials. Polyurethanes are a versatile class of polymers that have a wide range of properties and can be used for a variety of applications. Some common uses of polyurethanes made from MDI include:

Insulation

Rigid polyurethane foam is used as insulation in buildings, appliances, and refrigeration equipment.

Flexible foam

Flexible polyurethane foam is used in a wide range of applications, including seating, bedding, and carpet underlay.

Coatings and adhesives

Polyurethane coatings and adhesives are used in a wide range of industrial and consumer applications.

Elastomers

Polyurethane elastomers are used in a wide range of applications, including automotive parts, rollers, and seals.

Polyurea

MDI is also used in the production of polyurea, which is a type of polymer that can be used for coatings, linings, and sealants.

MDI also has other application in electronic, packaging and construction industries.

Because of its versatility and unique properties, MDI and polyurethanes made from it have a wide range of applications in various industries and have become an important class of materials in modern society.

How is MDI produced

MDI is produced through a multi-step process that involves the reaction of aniline, formaldehyde, and phosgene. The process can be broken down into several stages:

Aniline is first converted to aniline hydrochloride using hydrochloric acid.

The aniline hydrochloride is then reacted with formaldehyde to form a mixture of mono- and di-methylol aniline.

The mono- and di-methylol aniline is then reacted with phosgene to produce MDI and a by-product called polycarbonate diol.

The MDI is then purified and distilled to remove impurities and by-products.

The purified MDI is then cooled and stored in tanks for further use.

The process of MDI production can vary depending on the manufacturer and the specific technology used, and it’s worth noting that some of the feedstocks and intermediate chemicals used in the process are highly toxic and require special handling and safety measures.

An alternative method of producing MDI is through the reaction of hydrogen cyanide, formaldehyde and aniline, which is known as the “HCN route”

Also there is another method that uses methanol, formaldehyde, and aniline, called “methanol route” which is becoming increasingly popular due to its lower cost and lower toxicity.

What are the key feedstocks of MDI

MDI stands for Methylene Diphenyl Diisocyanate, which is a key raw material in the production of polyurethane (PU) materials. The key feedstocks for the production of MDI are:

Aniline

Aniline is an important feedstock for the production of MDI. It is a colorless, oily, and highly toxic liquid that is used as an intermediate in the production of a variety of industrial chemicals, including MDI.

Phosgene

Phosgene is a highly toxic gas that is used as a reactant in the production of MDI. It is used to form the isocyanate group that is essential for the production of PU materials.

Hydrogen cyanide (HCN)

Hydrogen cyanide is another key feedstock for the production of MDI. It is used as a reactant in the production of amines, which are intermediates in the production of MDI.

Methanol

Methanol is another key feedstock for the production of MDI. It is used as a reactant in the production of amines, which are intermediates in the production of MDI.

It’s worth noting that the feedstocks used for MDI production can vary depending on the specific process used by the manufacturer and some of the feedstocks are highly toxic and require special handling and safety measures.

What types of MDI are there

There are several types of MDI, each with slightly different properties and applications. Some common types of MDI include:

Pure MDI

This is the most basic form of MDI, it is a colorless, flammable liquid that is used as a raw material in the production of polyurethane (PU) materials.

Polymeric MDI (PMDI)

This is a form of MDI that contains a small amount of polyurethane polymer. It is used primarily in the production of spray polyurethane foam insulation, and other types of insulation.

These are some of the common types of MDI. However, there are other specialized types as well which are used in specific industrial or research applications. The choice of MDI type will depend on the properties required for the final product and the production process.

Which industries use MDI

MDI is used in a wide range of industries due to its versatility and unique properties. Some common industries that use MDI include:

Construction

MDI is used in the production of insulation materials, such as rigid foam insulation for buildings and appliances, as well as in coatings and adhesives for construction applications.

Automotive

MDI is used in the production of flexible foam for car seats, as well as in elastomers for automotive parts such as seals, hoses, and bushings.

Furniture

MDI is used in the production of flexible foam for furniture and bedding products, as well as in coatings and adhesives.

Electronics

MDI is used in the production of coatings, adhesives, and sealants for electronic applications.

Packaging

MDI is used in the production of coatings and adhesives for packaging applications.

Coatings

MDI is used in the production of coatings and sealants for industrial and consumer applications.

Polyurea

MDI is also used in the production of polyurea, which is a type of polymer that can be used for coatings, linings, and sealants.

Adhesives

MDI is used in the production of adhesives for industrial and consumer applications.

MDI Market information

The largest producers of MDI are China, Europe, and North America. According to statistics, China is the largest producer of MDI in the world, followed by Europe and North America. The large production of MDI in China is due to a number of factors, including a large domestic market for the product, low labor costs, and government support for the industry. Europe and North America have also a significant production of MDI, due to its high demand in the construction, automotive and furniture industries.

The global methylene diphenyl diisocyanate (MDI) market size was valued at around USD 10 billion in 2020, and it is expected to grow at a CAGR of around 6% during the forecast period from 2021 to 2028. The market is driven by the increasing demand for polyurethane (PU) products in various end-use industries such as construction, automotive, furniture, and electronics.

The growing construction industry, particularly in developing countries, is expected to drive the demand for MDI as PU insulation materials are widely used in buildings, appliances and refrigeration equipment. The automotive industry is also a significant consumer of MDI as it is used to produce flexible foam for car seats and elastomers for automotive parts such as seals, hoses, and bushings.

The furniture industry is also a significant consumer of MDI, as it is used to produce flexible foam for furniture and bedding products, as well as in coatings and adhesives.

The demand for MDI is also driven by the increasing use of polyurea in various applications such as coatings, linings, and sealants.

However, the market growth could be affected by factors such as the high cost of raw materials and the stringent regulations related to the handling and disposal of isocyanates, which are the precursors to MDI.

Overall, the global MDI market is expected to continue growing in the forecast period, driven by the increasing demand for PU products in various end-use industries.

According to https://oec.world/ :

Amino-resins, polymethylene phenyl isocyanate (crude MDI, polymeric MDI) are the world’s 593rd most traded product.

In 2020, the top exporters of Amino-resins, polymethylene phenyl isocyanate (crude MDI, polymeric MDI) were China ($813M), Germany ($731M), Belgium ($549M), Netherlands ($534M), and Saudi Arabia ($380M).

In 2020, the top importers of Amino-resins, polymethylene phenyl isocyanate (crude MDI, polymeric MDI) were China ($468M), Netherlands ($370M), United States ($267M), Canada ($248M), and Turkey ($241M).

Further information

- Wikipedia for general, history, production and usage information

- PubChem for chemistry and property information

Business Analytiq

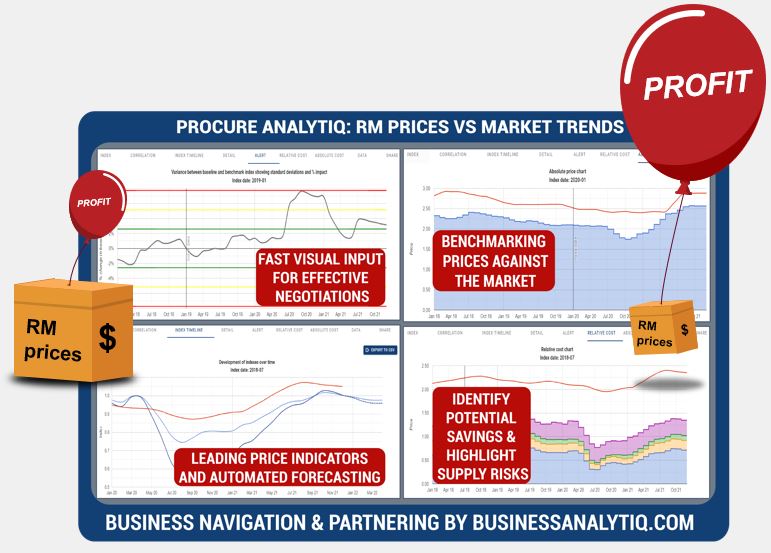

BE THE FIRST TO SEE RISK AND OPPORTUNITY!

BusinessAnalytiq provides unlimited market trend data and an online tools to track market developments, key benchmarks & leading indicators.

BusinessAnalytiq leads to price visibility, better negotiations, easier budgeting and forecasting, lower raw material prices, and improved better internal and external communication. BusinessAnalytiq will decrease risk and higher profit.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page