Polylactic acid (PLA) price January 2025 and outlook (see chart below)

- North America:US$2.24/KG, -4.3% down

- Europe:US$2.92/KG, -3.6% down

- Northeast Asia:US$2.45/KG, -3.2% down

- Southeast Asia:US$2.48/KG, -2.7% down

Business Analytiq assumes no responsibility or liability for any errors or omissions in the content of this site. The information contained in this site is provided on an “as is” basis with no guarantees of completeness, accuracy, usefulness, or timeliness.

Polylactic acid (PLA) price index

This post is a summary of the polylactic acid price developments. The price developments of polylactic acid are expressed in US$ prices converted FX rates applicable at the time when the price was valid. Polylactic price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

The outlook for polylactic prices, on the second tab, is generated from different inputs including:

- Very recent price developments of immediate cost drivers of polylactic acid prices

- Recent price developments of underlying feedstocks which drive the price of polylactic acid

- Market futures for both cost drives and feedstocks of polylactic acid prices

- Adjustment of current supply/demand imbalances in the polylactic acid market

- Longer term trends in likely demand conditions

Further information on the Polylactic acid (PLA) price chart

What is Polylactic acid (PLA)

Polylactic acid (PLA) is a thermoplastic polymer made from renewable resources such as corn starch, sugarcane, or cassava roots. It is commonly used as a substitute for petroleum-based plastics in various applications, including packaging, disposable tableware, and 3D printing filaments.

One of the key advantages of PLA is its biodegradability and compostability, which makes it a more environmentally friendly alternative to traditional petroleum-based plastics. It is also considered safe for food contact applications and has a low carbon footprint compared to traditional petroleum-based plastics.

However, the properties of PLA can be affected by factors such as temperature, moisture, and UV exposure, which can limit its use in some applications. In addition, the production of PLA from renewable resources can also be limited by factors such as the availability and cost of raw materials, as well as the efficiency of the production processes.

Despite these challenges, the demand for PLA is growing, driven by increasing concerns about the environmental impact of traditional petroleum-based plastics and the push for more sustainable materials and products. As a result, the market for PLA is expected to continue growing in the coming years, with new applications and production processes being developed to meet changing market demands.

How is Polylactic acid (PLA) produced

Polylactic acid (PLA) is produced through a process called polymerization, which involves the conversion of lactic acid monomers into a polymer chain. The main steps involved in the production of PLA are:

Fermentation

Lactic acid is produced through the fermentation of renewable resources such as corn starch, sugarcane, or cassava roots. This involves the use of bacteria or yeast to convert the carbohydrates in these resources into lactic acid.

Purification

The lactic acid produced in the fermentation process is then purified to remove impurities and improve its quality.

Polymerization

The purified lactic acid is then polymerized to form a polymer chain, which is the basic building block of PLA. This can be done through several methods, including solution polymerization, melt polymerization, and ring-opening polymerization.

Pelletization

The polymerized PLA is then pelletized, which involves cooling and solidifying the polymer into small pellets. This makes it easier to transport and handle the material, as well as to process it further into various products.

Processing

The pellets can then be processed into various products, such as packaging, disposable tableware, and 3D printing filaments, through techniques such as injection molding, blow molding, and extrusion.

The production of PLA is a complex process that involves several steps and the use of specialized equipment and materials. The efficiency and cost of the production process can be affected by factors such as the availability and cost of raw materials, the efficiency of the polymerization process, and the availability of specialized equipment and materials. As a result, the production of PLA is constantly evolving, with new and improved processes being developed to meet changing market demands and improve efficiency.

What drives the cost of Polylactic acid (PLA)

The cost of Polylactic acid (PLA) is driven by several factors, including:

Raw material costs

The cost of the raw materials used to produce PLA, such as corn starch, sugarcane, or cassava roots, is a major factor in determining the cost of the finished product. Fluctuations in the prices of these raw materials can have a significant impact on the cost of PLA.

Energy costs

The production of PLA requires a significant amount of energy, which can also contribute to the cost of the finished product. Energy costs, such as electricity and fuel prices, can have a significant impact on the cost of PLA production.

Production processes

The efficiency and cost of the production processes used to produce PLA can also impact the cost of the finished product. For example, advances in polymerization processes can lead to improved efficiency and lower costs, while the use of more expensive materials and specialized equipment can increase costs.

Regulations and policies

Regulations and policies related to the use and disposal of plastics can also impact the cost of PLA. For example, regulations that encourage the use of biodegradable materials or that impose fees or taxes on the use of traditional petroleum-based plastics can increase the cost of PLA.

These are some of the main factors that drive the cost of PLA, but other factors, such as exchange rates, transportation costs, and tariffs, can also have an impact. The cost of PLA is constantly changing, driven by fluctuations in these and other factors, and it is important for manufacturers and users of the material to be aware of these changes and to adjust their operations accordingly.

What is Polylactic acid (PLA) used for

Polylactic acid (PLA) is a thermoplastic polymer that is commonly used in various applications, including:

Packaging

PLA is used as a substitute for petroleum-based plastics in packaging applications, including food packaging, retail packaging, and medical packaging. Its biodegradability and compostability make it a more environmentally friendly alternative to traditional petroleum-based plastics.

Disposable tableware

PLA is used to produce disposable tableware, including cups, plates, and cutlery. Its biodegradability and compostability make it a more sustainable alternative to traditional petroleum-based plastics, especially in applications where single-use products are required.

3D Printing

PLA is commonly used as a filament in 3D printing, as it is easy to work with and produces high-quality parts. It is widely used in applications such as prototyping, product design, and education.

Textile and Fabric

PLA is used in the production of fibers and fabrics, and as a filling material in various products such as pillows, cushions, and bedding.

Biodegradable plastics

PLA is used as a biodegradable alternative to traditional petroleum-based plastics in applications such as agriculture and horticulture, where the material can be used to produce biodegradable mulch films, pots, and trays.

These are some of the main applications of PLA, but the material is also used in a variety of other applications, such as medical implants, automotive parts, and electronics. The demand for PLA is growing, driven by increasing concerns about the environmental impact of traditional petroleum-based plastics and the push for more sustainable materials and products. As a result, new applications and uses for PLA are being developed to meet changing market demands.

What types of Polylactic acid (PLA) are there

There are several types of Polylactic acid (PLA) that are differentiated based on the properties and applications of the material. Some of the most common types of PLA include:

Injection Molding PLA

This type of PLA is used in applications that require high strength and dimensional stability, such as the production of automotive parts, toys, and household goods.

Blown Film PLA

This type of PLA is used in applications that require high clarity and transparency, such as food packaging and retail packaging.

Fiber-grade PLA

This type of PLA is used in applications that require high strength and flexibility, such as the production of textiles and fabrics.

Medical-grade PLA

This type of PLA is used in medical applications, such as the production of sutures and implants. Medical-grade PLA is made to strict standards to ensure its biocompatibility and performance in medical applications.

High-Temperature PLA

This type of PLA is used in applications that require high heat resistance, such as the production of hot-fill containers and lids.

Biodegradable PLA

This type of PLA is used in applications that require biodegradability and compostability, such as food packaging and disposable tableware.

These are some of the main types of PLA, but the material can be modified and blended with other materials to achieve specific properties and performance characteristics for specific applications. The type of PLA used for a particular application will depend on the specific requirements and specifications of that application, as well as the end-use performance and environmental requirements of the material.

What are key properties of PLA

Polylactic acid (PLA) is a biodegradable and compostable thermoplastic polymer that is derived from renewable resources such as corn starch, sugarcane, or cassava roots. Some of the key properties of PLA include:

Biodegradability and compostability

PLA is a biodegradable and compostable material, meaning that it can break down and return to the environment as organic matter in a relatively short period of time.

Renewable source

PLA is made from renewable resources, making it a more sustainable alternative to traditional petroleum-based plastics.

Strength and stiffness

PLA has good strength and stiffness properties, making it suitable for a range of applications that require these properties, such as packaging and product components.

Heat resistance

PLA has a relatively low melting temperature and is not suitable for applications that require high heat resistance. However, modified forms of PLA with improved heat resistance are available for specific applications.

Clarity and transparency

PLA has good clarity and transparency, making it suitable for applications that require these properties, such as food packaging and retail packaging.

Barrier properties

PLA has good barrier properties, meaning that it can help to protect the contents of the package from moisture, gases, and other environmental factors.

Printability

PLA is a printable material, making it suitable for applications that require high-quality printing, such as retail packaging and promotional materials.

Dimensional stability

PLA has good dimensional stability, meaning that it retains its shape and size over time, making it suitable for applications that require precise dimensional tolerances, such as product components.

These are some of the key properties of PLA, and the specific properties of the material can vary depending on the type of PLA and the processing conditions used to produce it. In general, PLA is a versatile and sustainable material that is well-suited for a range of applications, making it an increasingly popular alternative to traditional petroleum-based plastics.

How big is the global Polylactic acid (PLA) market

The global Polylactic Acid (PLA) market has been growing rapidly in recent years, driven by the increasing demand for environmentally sustainable and biodegradable materials. According to a report by Grand View Research, the global PLA market size was valued at USD 3.2 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 17.2% from 2021 to 2028.

The growth of the global PLA market can be attributed to several factors, including the increasing demand for biodegradable and compostable packaging materials, the growing use of PLA in medical and healthcare applications, and the increasing demand for renewable and sustainable materials. Additionally, the development of new processing technologies and the introduction of new grades of PLA with improved properties are also driving the growth of the global PLA market.

The Asia-Pacific region is expected to be the largest market for PLA, due to the growing demand for environmentally sustainable materials and the increasing use of PLA in the packaging, medical, and agriculture industries. Europe and North America are also expected to be significant markets for PLA, driven by the increasing demand for biodegradable and compostable materials in these regions.

In conclusion, the global PLA market is expected to continue its strong growth in the coming years, driven by the increasing demand for sustainable and biodegradable materials, as well as the growing use of PLA in a range of applications.

According to https://oec.world/ :

Polylactic acid are the world’s 2612th most traded product.

In 2020, the top exporters of Polylactic acid were United States ($234M), Netherlands ($160M), Thailand ($114M), Germany ($18.8M), and China ($15M).

In 2020, the top importers of Polylactic acid were Netherlands ($108M), Germany ($82.2M), China ($73M), Chinese Taipei ($69.6M), and Italy ($61.6M).

Which countries produce the most PLA

The production of Polylactic Acid (PLA) is a rapidly growing industry, with several countries contributing to the global supply. Some of the major producers of PLA include:

China

China is the largest producer of PLA in the world and is home to several leading producers of the material, including TongDa and NatureWorks.

United States

The United States is home to one of the largest producers of PLA, NatureWorks, which is based in Minnesota.

Europe

Europe is home to several leading producers of PLA, including FKuR in Germany and Synbra in the Netherlands.

Japan

Japan is home to several leading producers of PLA, including Teijin and Mitsubishi Chemical.

South Korea

South Korea is home to several leading producers of PLA, including SK Chemicals and Hanwha Chemical.

These countries are among the largest producers of PLA in the world, and their contribution to the global supply of the material is expected to grow in the coming years, driven by the increasing demand for sustainable and biodegradable materials. In addition to these countries, several other countries, including India, Brazil, and Australia, are also contributing to the global supply of PLA.

Who are the major Polylactic acid (PLA) producers

The Polylactic Acid (PLA) market is dominated by a few major companies that are among the largest producers of the material in the world. Some of the leading companies in the global PLA market include:

NatureWorks LLC

NatureWorks is a leading producer of PLA and is based in the United States. The company produces a range of grades of PLA, including Ingeo, which is a biodegradable and compostable material used in a variety of applications.

FKuR Kunststoff GmbH

FKuR is a German company that is a leading producer of bioplastics, including PLA. The company produces a range of grades of PLA, including bio-based materials and biodegradable materials.

Teijin Limited

Teijin is a Japanese company that is a leading producer of PLA. The company produces a range of grades of PLA, including materials that are biodegradable and compostable.

Synbra Technology B.V.

Synbra is a Dutch company that is a leading producer of bioplastics, including PLA. The company produces a range of grades of PLA, including bio-based materials and biodegradable materials.

SK Chemicals Co., Ltd.

SK Chemicals is a South Korean company that is a leading producer of PLA. The company produces a range of grades of PLA, including materials that are biodegradable and compostable.

These are some of the largest producers of PLA in the world, and their contribution to the global supply of the material is expected to grow in the coming years, driven by the increasing demand for sustainable and biodegradable materials.

Further information

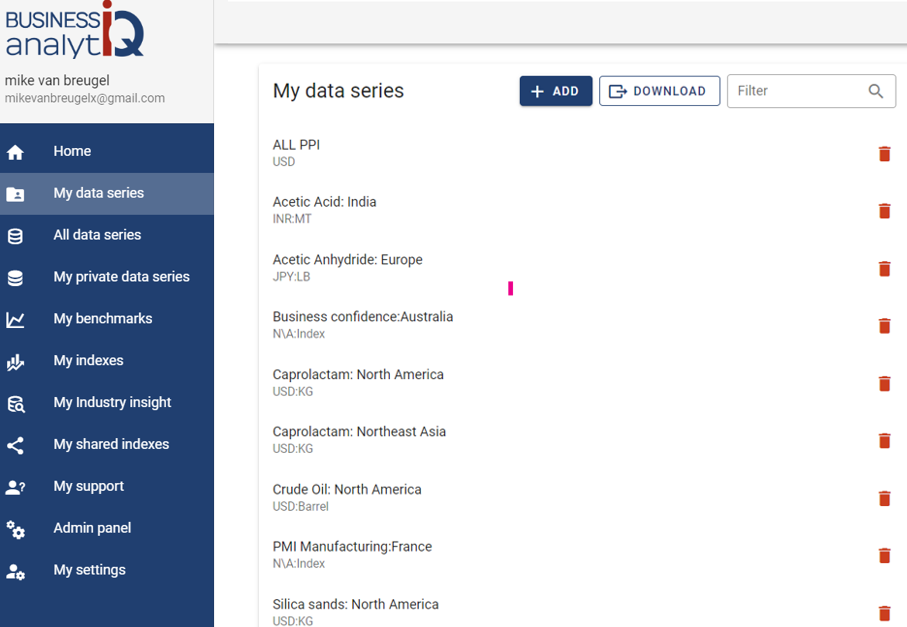

NEED A QUICK DOWNLOAD?

ACCESS TO OUR FULL DATABASE IS US$399/YEAR, WITH A 30-DAY $30 TRIAL

GET THAT DOWNLOAD IN 3 MINUTES!

BusinessAnalytiq provides a database of hundreds of market & price trend data, as well as online tools to set up benchmarks and leading indicators.

Where does the data come from?

- The source of the data are exclusively public non-confidential sources. We have no access to primary data

- This the index trend of the price trend of the "product category" in general, and not a single specification of the product in particular

- The data is a combination of contract and spot pricing

- Our algorithms are set up to eliminate significant product mix impact on the reported price

- We combine public publications, import/export records, trading prices, company announcements, magazine articles, tweets, and other sources of ad-hoc public information.

- The chart shows the our best approximation of the market trend based on our algorithm interpretation of the signals

- For most indexes we have multiple sources and we focus on using statistically-correlated sources

- As a function of our automation, it is likely that recent trends will be adjusted as we discover more information. So, for example, the price trend for February 2024 will be first calculated in February 2024 and adjusted in March, April and May 2024.

- We will update the data trend as more information becomes available, and this means that recent trends will always be adjusted as we get more data available

- The algorithm will regularly revise our understanding of market trends, and indicated market trends may change

- The data is presented in US$. The UOM of measure is shown in the Index list table

- Our automated software and we do our best to create an accurate representation of the trend

Where does the data NOT come from?

- We do not purchase data from any other source and republish it.

- We will not purchase data from any other source and republish it

- We do not extrapolate trends, even for the forecast. We look for other market signals and leading indicators

What data should our company use?

- If you are making decisions driving significant share of profit, we always recommend that you buy data from the companies who invest in direct primary market access such as ICIS, amongst many others

- Our data, at best, represents an estimate of the market trend based on public information

- We have no direct access to the market, and we do not interview suppliers and customers

- Our automated analysis tools in the online software are set up to combine our data with other sources of data

- We do not recommend that you use our data for direct price mechanisms, as we may change and improve the data trends over time, including historical data

What does the quality indication in the main menu mean?

- Quality level A: Data is from a reliable and confirmed source

- Quality level B: Data is from multiple credible sources and there are no major statistical inconsistencies between them

- Quality level C: Data is from multiple credible sources and there are some statistical inconsistencies between them

- Quality level D: Data is from a single credible source, but we cannot verify the data

- Quality level E: Data is either:

- From a single source, which we consider reliable, but we cannot verify the data.

- From 2 or more sources which have some periods of contradicting trends.

- Quality level F: Data is from a single source which we consider indicatively correct, but the data is anecdotal and we cannot verify the data.

What are the disclaimers?

- We assume no responsibility or liability for any errors or omissions in the content of this site.

- The information is provided on an “as is” basis with no guarantee of completeness, accuracy, usefulness, fitness for purpose or timeliness.

- By their nature, outlooks are always uncertain

How often do we update the data?

- We aim to update the data series on the 9th and 24th of each month (but we do not always make it for each chart)

- The data for the current month and recent history are fine-tuned over time.

What are we doing to improve the data?

- We are continually improving our data collection and processing methods

- Pricing data will be updated from time to time as we improve the accuracy

- We are reviewing all data sources in the first half of 2024.

- There will be continuous fine-tuning of the trend and forecast algorithm as part of that.

- The key focus in 2024 is to add many additional indexes

How can i give feedback on the data or request for new indexes

- Feel free to contact us if you have a specific request. You can reach us via the Contact us page